System Cameras

System cameras with a wide range of interchangeable lenses

Compact and robust design with protection up to IP67

Available in various equipment and performance configurations

Ideal for customized thermographic solutions

Reliable use even in demanding industrial environments

System Cameras for Industrial and Laboratory Use

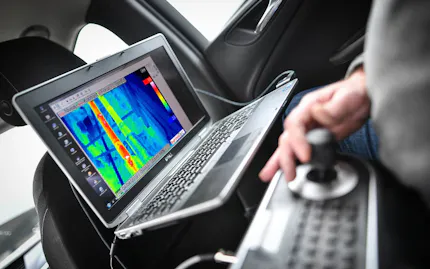

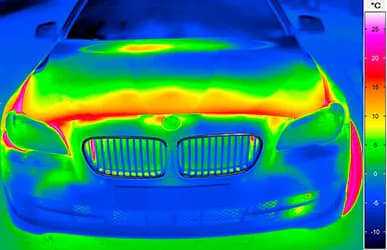

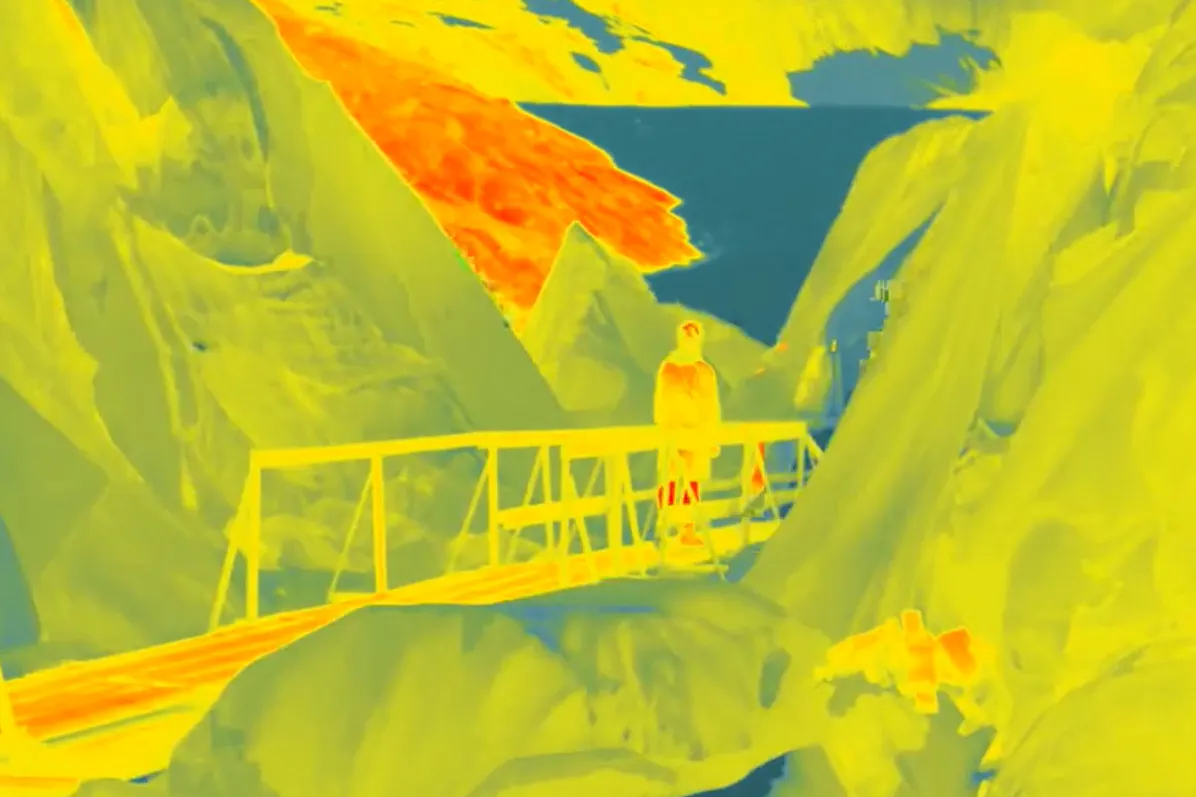

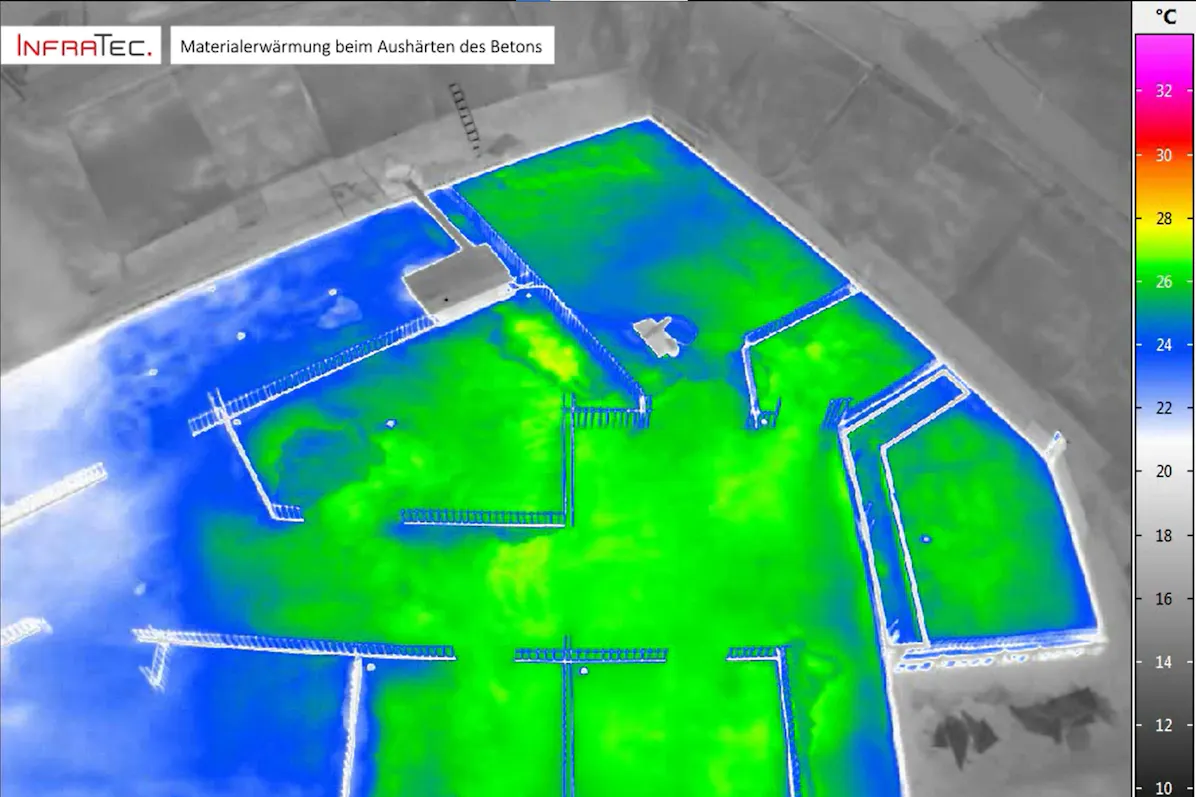

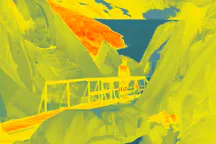

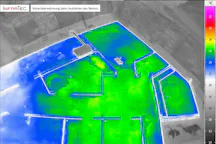

A wide range of interchangeable lenses and the compact housing dimensions of our system cameras as well as the robust construction with a degree of protection up to IP67 make these infrared cameras useful tools for many areas of application in industry and research. They can be easily integrated into existing system environments by using the Software Development Kit (SDK). All system camera series are available in numerous equipment and performance variants and enable - depending on the application focus and requirements - individual thermography solutions.

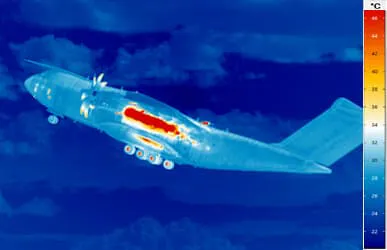

We offer a variety of flexibly usable system camera models of different performance classes and spectral sensitivity ranges. These include the ImageIR® series cameras measuring in the short-wave infrared range, which are predestined for high-temperature applications. The universally applicable cameras of the VarioCAM® HD head product series, on the other hand, are particularly suitable for demanding measuring and monitoring tasks.

The respective service package includes the control and analysis programme of the IRBIS® software family developed by us. Among other things, it allows the collected temperature measurement data to be analysed and evaluated.

Detector Formats of System Cameras

| Detecor fomat / MicroScan resolution (IR pixels) | (1,024 × 768) / (2,048 × 1,536) | (1,280 × 1,024) | (1,024 × 768) | (640 × 480) | (640 × 512) |

| VarioCAM® HD head | ◼ | ◼ | |||

| VarioCAM® HDx head | ◼ | ||||

| ImageIR® 6300 | ◼ | ||||

| ImageIR® 8100 | ◼ | ||||

| ImageIR® 9100 | ◼ | ||||

| Pir uc SWIR HD 800 | ◼ |

Configure Your Camera System

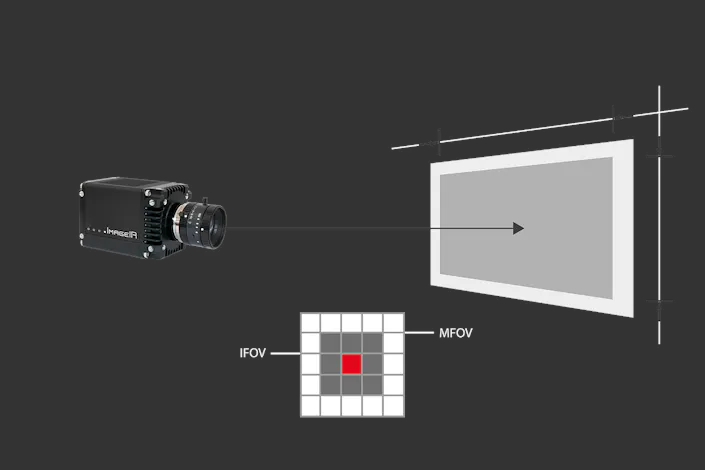

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

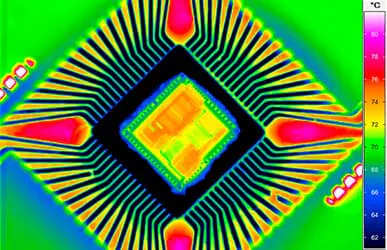

Infrared Camera Series VarioCAM® HD head and VarioCAM® HDx head

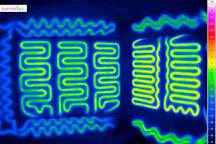

The infrared cameras of the VarioCAM® HD head and VarioCAM® HDx head series from InfraTec are based on uncooled microbolometer FPA detectors. With up to (1,024 × 768) IR pixels, the camera series delivers brilliant and detailed 16-bit thermal images with an outstanding frame rate of up to 240 Hz. Due to the optional opto-mechanical MicroScan unit, even IR image formats with a geometrical resolution of 3.1 megapixels are achieved, which manifests itself in even greater image sharpness and imaging quality. This means that geometrically induced measurement errors on complexly structured objects can be reliably avoided. In combination with an excellent thermal resolution of up to 20 mK, these infrared cameras are suitable for demanding stationary measurement and inspection tasks in manufacturing, quality assurance and process optimisation as well as research and development.

The camera series is equipped with a shock proof light metal housing that keeps out dust, dirt, and water and, if desired, meets the requirements of IP67 protection. The robust construction and compact housing dimensions easily allow installation in the harshest process environments.

The camera series supports industry-wide standards for data transfer and image processing with GigE-Vision and GeniCam. This means that each model can not only be used for computer-aided laboratory applications via InfraTec's efficient and convenient IRBIS® thermography software, but - based on these standards - also allows rapid integration into existing system environments.

High-end detectors with up to (1,024 × 768) infrared pixels

Available with unique opto-mechanical micro-scanner for up to (2,048 × 1,536) infrared pixels

Thermal resolution as low as 0.02 K

Frame rate up to 240 Hz

Cameras for fixed mount use in harsh process environments as well as for computer-assisted laboratory tasks

System Camera Series ImageIR® 6300

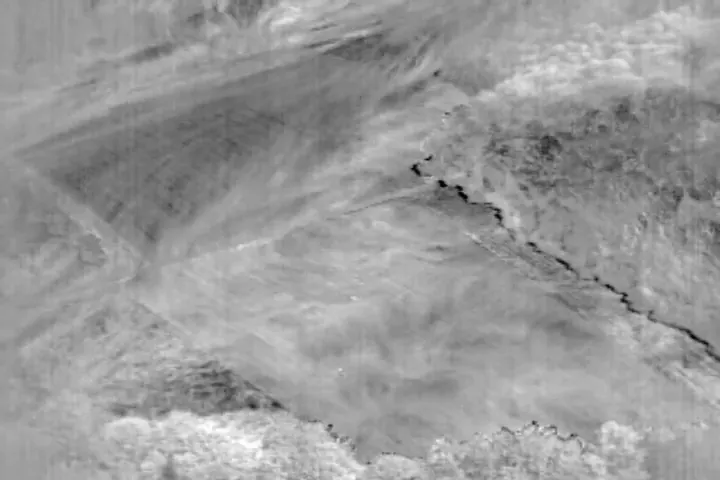

The radiometrically calibrated system camera ImageIR® 6300 is equipped with a cooled focal plane array photon detector of the latest generation. By combining the detector format of (640 × 512) IR pixels with the very small pixel pitch of 10 µm, the camera delivers razor-sharp images. Due to its snapshot mode, moving objects can also be displayed without distortion. The innovative XBn detector technology allows the detector to be operated at a significantly higher working temperature than the usual approximately 80 K. This allows the size, weight and power (SWaP) of the integrated detector/cooler unit to be minimised.

The ImageIR® 6300 is the first model in the ImageIR® series to feature a new integrated operating system. This opens up a wide range of new functions, such as fully autonomous camera operation without the need for an additional control PC. The camera can also be controlled via a web interface using a smartphone or tablet. In addition, users can run their own software directly on the camera and access the data stream directly via the integrated SDK. Together with the option of power supply via a wide-range input (9–36 V) or Power over Ethernet (PoE), these features make the the infrared camera much easier to use. This is particularly true for plant-integrated applications and in hard-to-reach places.

Infrared Cameras ImageIR® 8100 and ImageIR® 9100

The SWIR infrared cameras ImageIR® 8100 and ImageIR® 9100 are radiometrically calibrated and available with (640 × 512) or (1,280 × 1,024) IR pixels in VGA or SXGA image format. They operate in the short-wave infrared range and allow, among other things, emissivity-optimised measurements of temperatures on metallic surfaces. Due to the resulting small detector chip diagonals, a pixel pitch of only 5 µm enables a comparatively cost-effective, compact optical design with high imaging quality. In combination with radiometric calibration, brilliant thermography images with high geometrical and thermal resolution can be achieved in both formats. The combination with interchangeable lenses of different focal lengths enables the comfortable adaptation of the image fields to real measurement scenarios.

Video Gallery System Cameras

You Need More Information about System Cameras?

There is system camera matching perfectly your specific requirements. To find out which one it is, just check out all the models in detail.