FIRE-SCAN for Li-Ion Batteries

Early Fire Detection in Warehouses and Assembly Halls

Automatic alarm triggering when critical temperature thresholds are exceeded

Segmentation of image areas for alerting

Documentation of alarm situations to analyse potential causes of fire

Localisation of heat sources, even in dusty or smoke polluted environments to prevent thermal runaway

Designed for continuous operation 24 h / 7 without supervision

Camera feed can be routed to control room or other locations

Single or multi-camera systems possible

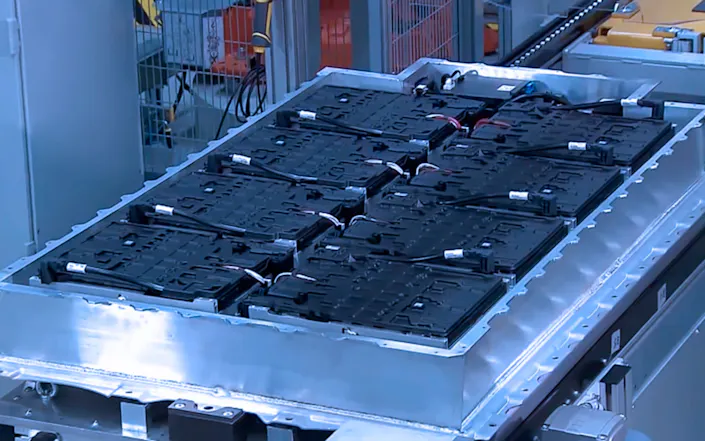

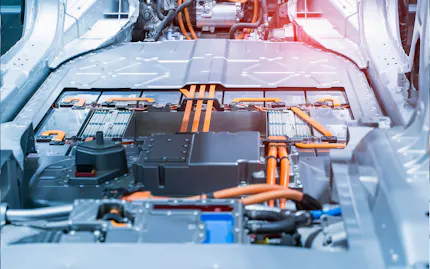

Electromobility – A future-oriented topic that manufacturers of electric vehicles and their suppliers are addressing to the same extent. The same applies to producers of high-performance rechargeable batteries and high-voltage batteries for use in electric cars, electric buses, e-scooters, e-mopeds and e-bikes. The production and storage of these energy storage devices entails some risks. Lithium-ion batteries in particular pose a fire hazard, as they can self-ignite in the event of a thermal runaway and release toxic gases when burning.

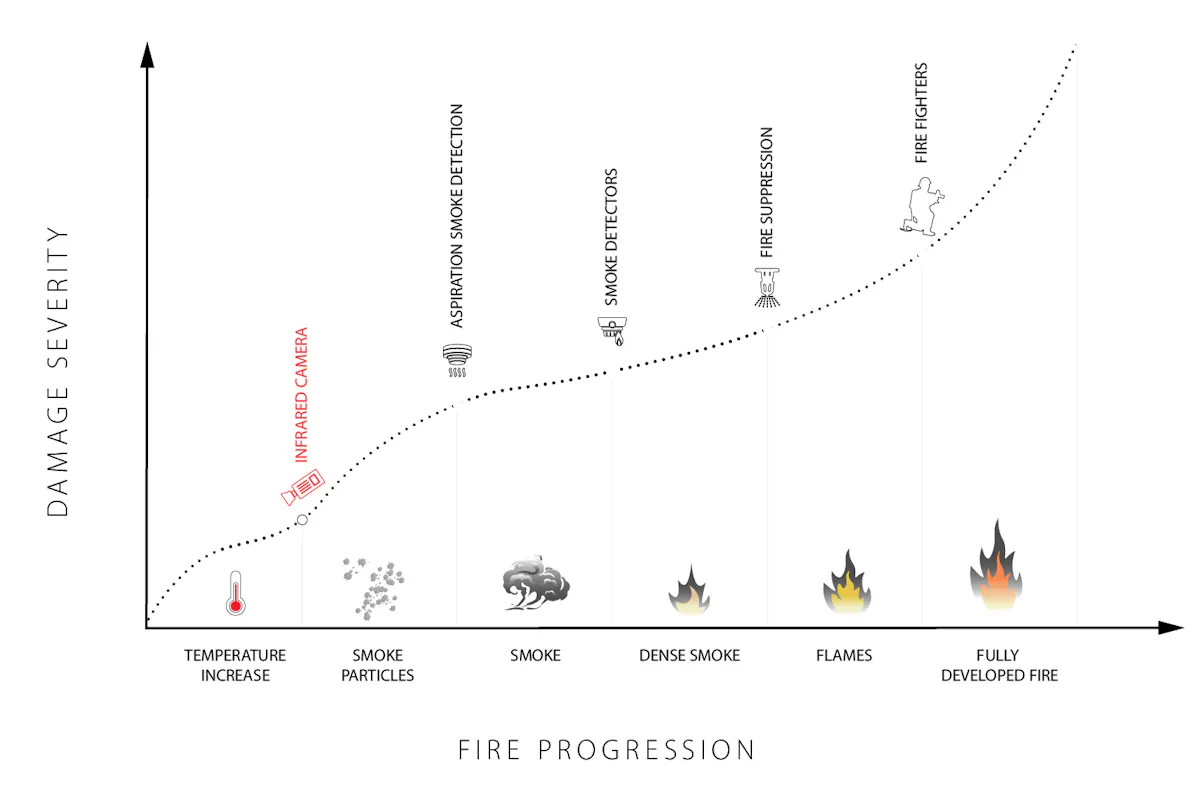

In order to avoid such a scenario, InfraTec offers a way to monitor assembly and storage halls completely automatically with the thermographic automation solution FIRE-SCAN. The system, consisting of a high-performance infrared camera and corresponding software, self-monitors the temperature development at workstations and storage areas 24 hours a day and reliably localises heat sources, before a thermal runaway occurs. If configurable temperature alarm set points are exceeded in selected areas of the thermal image, FIRE-SCAN triggers an automatic alarm before critical temperatures are reached and enables rapid intervention to prevent a fire.

Advantages of the FIRE-SCAN Thermography System

Large detector with highest geometric and thermal resolution

Analysis of temperature changes and gradients in full frame

Standard interface for easy integration into existing process environments

Camera operation under harsh environmental conditions

Robust metal housing for wide range of environmental conditions and IP rating requirements

Thermographic Warehouse Monitoring for Fire Prevention

Thermography in early fire detection: challenges, important parameters and their influence

FIRE-SCAN for thermographic warehouse monitoring

FIRE-SCAN for monitoring Lithium-ion batteries

High resolution infrared cameras with pan/tilt heads

Special infrared cameras for stationary installation

Thermography Systems for Early Fire Protection

Alarm Release

Automatic alarm release when temperature values exceed critical thresholds

Multi-stage alarming functionality for controlled escalation

Selection of subareas (sectors) within the thermal image

Logging and analysis of long-term temperature trends with adjustable time basis

Documentation of alarm situations to analyse the potential causes of fire

Modular design concept for tailored solutions

Customised System Concept

Designed for continuous operation 24/7 without supervision

Camera feed can be routed to control room or other locations

Flexible wiring technology (copper or fibre optic cable)

Uninterruptible power supply*

System maintenance through integrated PC in the control cabinet (via remote control*)

High-performing Software

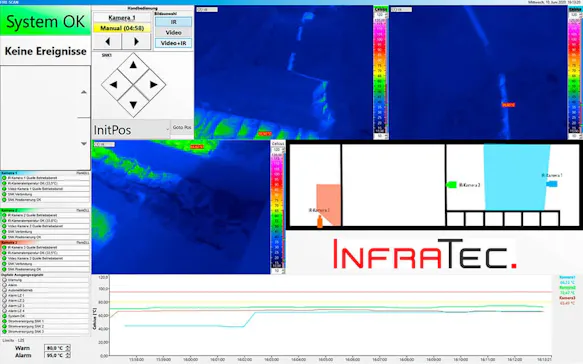

Continuous display of the current thermal images of all sectors (mosaic-overview)

Simultaneous display of thermographic and colour video live image*

Camera and system status indication

Merging of live images of thermography and video camera

Recording of maximum, minimum and average temperature of each sector

Single or multi-camera system available

Graphic data display of temperature-time profiles of all sectors

Logging of operations

Filing of image data

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

High-resolution Infrared Cameras

Uncooled FPA-Microbolometer detectors

High geometrical resolution and thermal sensitivity

High-contrast, brilliant thermal images

Localisation of hot spots even in dusty or smoke polluted environments

Spectral range (7.5 … 14) μm

Real-time data acquisition (Gigabit Ethernet)

Internal automatic calibration

Rugged housing according to industrial standard IP65

Pan/tilt systems to extend the detection areas*

Extremely high level of system availability

Digital colour video camera*

*optionally available

Product Flyer

Get all the information you need at a glance in our product flyers