Torpedo Car Hotspot Detection (THSD), Converter Hotspot Detection (CHSD) & Ladle Hotspot Detection (LHSD)

Customised system configuration

Full automatic observation of the plant during standard operation

Decentralised monitoring of measured values and system status

Easy to operate data presentation in the steel plant network

Remote access available

Installation of up to five infrared cameras

Display, evaluation and playback of recorded images as well as parameterisation, supervision and operation of the system

Detection of moving objects

Automated object recognition

Thermography for Safety in Steelworks

Thermographic system solutions from InfraTec offer a reliable and useful addition to safety measures in steelworks throughout the entire steel production process. As torpedo cars, converters and casting ladles are subject to constant stress, the lining can become worn over time, which in turn greatly increases the risk of breakthroughs.

Infrared cameras from InfraTec play a decisive role in preventing such scenarios. They can be used to monitor the condition of the refractory lining and any imminent breakthroughs around the clock.

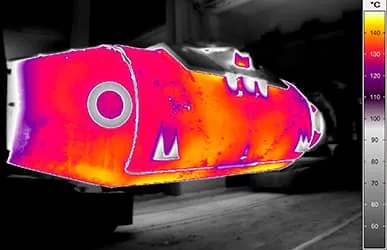

Torpedo Car Hotspot Detection – THSD

The Torpedo Hot Spot Detection (THSD) system uses the latest infrared technology to monitor the temperature of the torpedo steel structure. Two infrared cameras observe the torpedo cars while they are moving past the inspection site.

The temperature measurements are completely automatic and require no manual interaction. THSD automatically raises the alarm if an adjustable temperature threshold is overrun. This reliably prevents dangerous and loss-making breakouts of liquid iron.

THSD automatically tracks the temperature development of all torpedos in circulation. This allows to maximize the torpedo refractory lifetime without cutback of security and helps to save remarkable costs. THSD comes with highly reliable components in a flexible structure and thus is easily adoptable to the different situations and operational modes in iron and steel plants.

Benefits of the THSD System

Complete automatic thermographic temperature screening of the outer shell of all torpedos in circulation

Early detection of hotspots let keep you the close control of the refractory lining of your entire torpedo fleet

Secure protection against torpedo breakouts saves life, investments and long term operating ability of your shop

Optimisation of your torpedo fleet deployment improves the quality and saves time and energy

Prolongation of the torpedo refractory lifetime without cutback of security

Flexible structure for customised adoption to your operational modes

Return on investment within less than a year

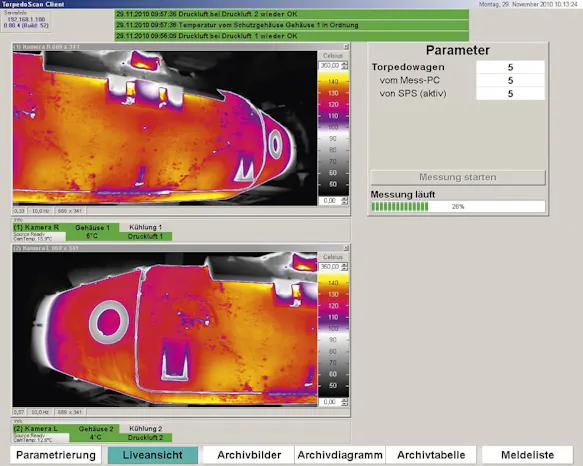

THSD Software

Full automatic operation without stopping the torpedo car

Reliable alarm release at defined pre and main alarm limits

Temperature trend recording and analysis for all torpedos

Customised system alignment and adjustment

Main window allows parameterisation, supervision, operation, display, evaluation and playback

Decentralised monitoring of system status and measured values

Recall of all recorded data for comparison and optimization

Easy to operate data presentation in the steel plant network

Remote access available

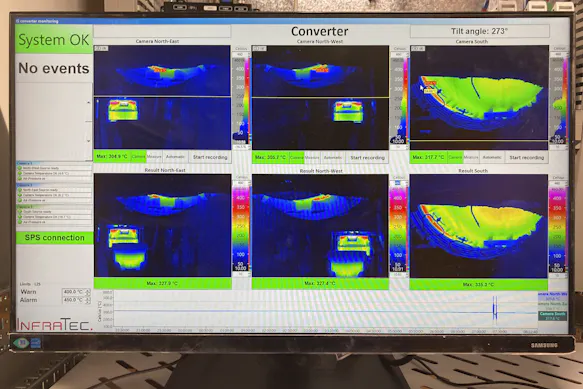

Converter Hot Spot Detection (CHSD)

In order to optimise the operating time of a converter between two feeds, it is necessary to permanently monitor its outer skin for increasing heating. This ensures that any breakthroughs are detected in the early stages. The thermography system records the temperatures of the converter surface over a large area and without contact, which are analysed using the associated special software. If the preset threshold values are exceeded, an automatic alarm is triggered. Repair or short-term ad hoc measures can then be initiated to ensure safety in the steelworks.

Up to three infrared cameras are used for monitoring, which are mounted in a circle below the converter. This enables monitoring from different perspectives. However, it is often not possible to monitor all critical points in a fixed converter position for environmental reasons. For this reason, the temperature must also be measured during repeated swivelling in a steel production cycle.

The measurement is fully automated, controlled by command telegrams from the connected PLC. The infrared cameras can also be controlled, started and stopped manually if required. This allows the operators to obtain a picture of the condition of certain areas of the converter at any time, independently of the automatic system, for example to investigate a suspicion based on other observations.

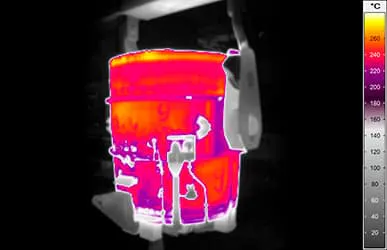

Ladle Hotspot Detection – LHSD

The Ladle Hot Spot Detection (LHSD) system uses Infrared (IR) technology to monitor the temperature of the ladle steel structure. Five infrared cameras observe the ladles while they are moved with the crane to the casting. The temperature measurements are made fully automatically without the need of any manual interaction. Optionally the ladle number can be recognised from characters on their surface. LHSD automatically raises the alarm if an adjustable temperature threshold is overrun. This reliably prevents dangerous and loss-making breakouts of liquid steel.

LHSD automatically tracks the temperature development of all ladles in circulation. This allows to maximize the ladle refractory lifetime without cutback of security and helps to save remarkable costs. LHSD comes with highly reliable components in a flexible structure and thus is easily adoptable to the different situations and operational modes in steel plants.

Benefits of the LHSD System

Complete automatic thermographic temperature screening of the outer shell of all ladles in circulation

Early detection of hotspots let keep you the close control of the refractory lining of your entire ladle fleet

Secure protection against ladle breakouts saves life, investments and long term operating ability of your shop

Optimisation of your ladle fleet deployment improves the quality and saves time and energy

Prolongation of the ladle refractory lifetime without cutback of security

Flexible structure for customised adoption to your operational modes

Return on investment within less than a year

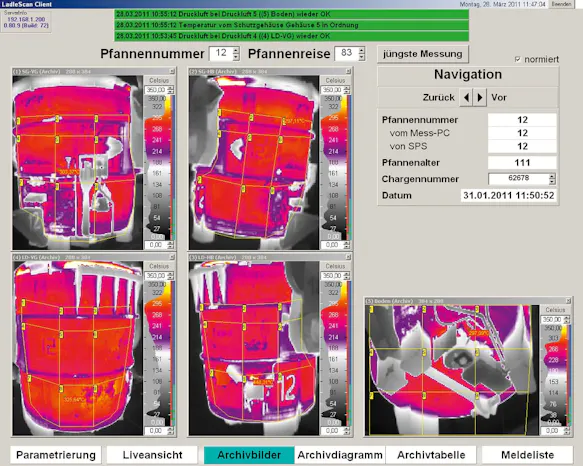

LHSD Software and System Features

Full automatic operation without stopping the crane

Reliable alarm release at defined pre and main alarm limits

Temperature trend recording and analysis for all ladles

Customised system alignment and adjustment

Main window allows parameterisation, supervision, operation, display, evaluation and playback

Decentralised monitoring of system status and measured values

Recall of all recorded data for comparison and optimization

Easy to operate data presentation in the steel plant network

Remote access available

Product Flyer

Get all the information you need at a glance in our product flyers