PIR uc 605

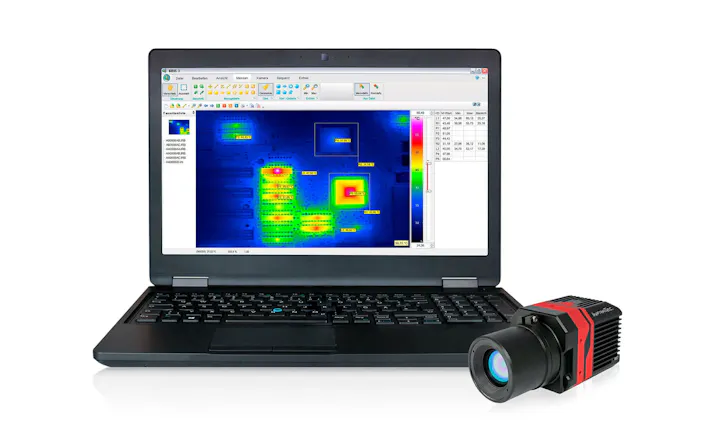

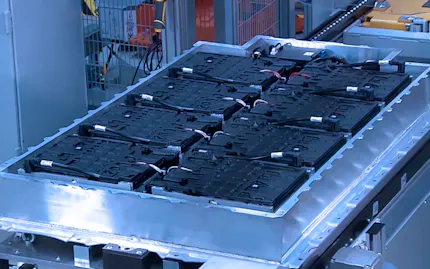

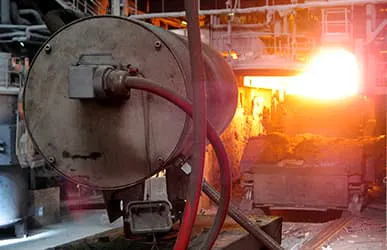

InfraTec’s radiometric infrared camera module PIR uc 605 is designed for universal use and enables the entry into stationary thermal imaging for research and development as well as into process optimisation.

Uncooled microbolometer FPA detector with (640 × 480) IR pixels

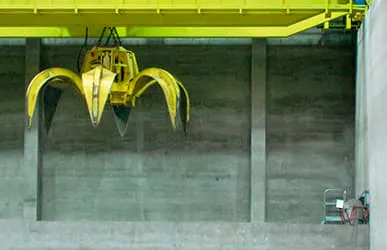

Small and robust light metal housing enables extensive range of applications

Includes comprehensive control and analysis software for a wide range of measuring tasks and applications

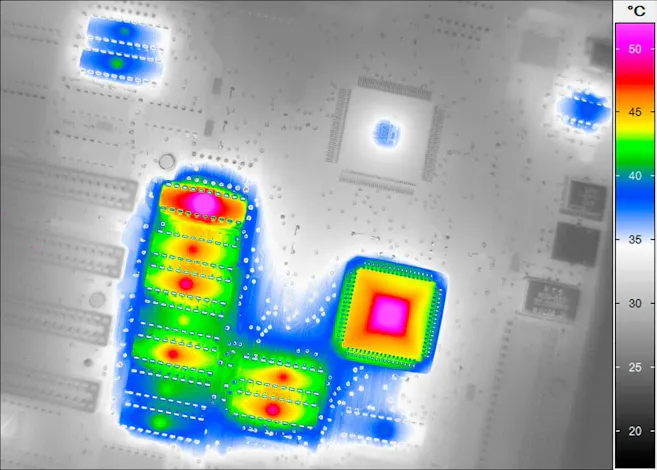

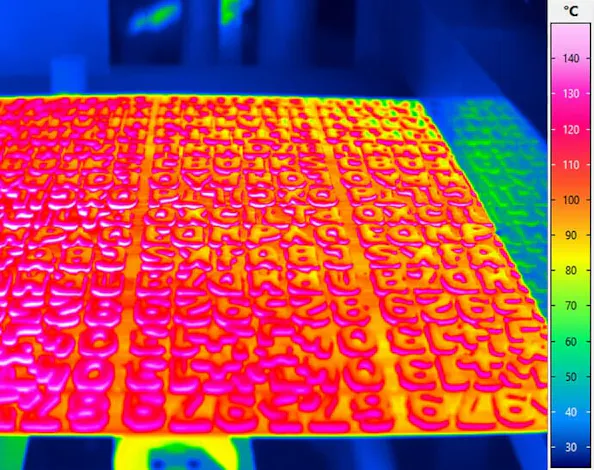

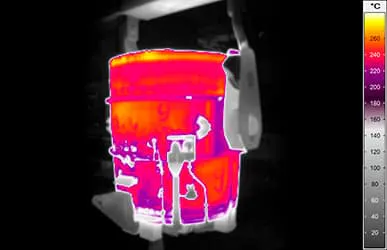

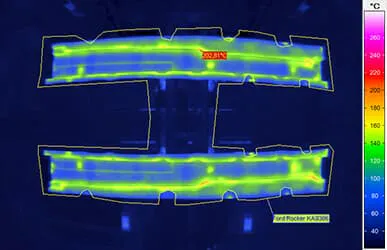

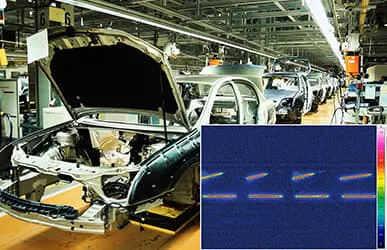

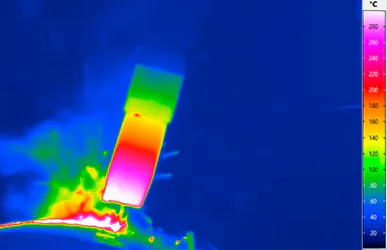

Thermographic images with high resolution for temperature measurement

Analysis of temperature changes and dynamic processes

Detection of small temperature differences

Wide range of lenses for optimal adaptation of the image geometry to the measuring situation

Extremely small and robust light metal housing

Comprehensive control and processing tools for a wide variety of measurement tasks and areas of application

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Technical Specifications

| Spectral range | (8 … 14) µm |

| Pitch | 17 μm |

| Detector | Uncooled Microbolometer Focal Plane Array |

| Detector format (IR pixels) | (640 × 480) |

| Temperature measuring range | (-20 … 400) °C, up to 1,000 °C* |

| Measurement accuracy | ± 5 K (0 … 100) °C, ± 5 % (< 0 respectively > 100) °C |

| Temperature resolution at 30 °C | ≤ 0.06 K |

| Frame rate | 25 Hz (640 × 480) |

* Depending on model

** In selected measurement ranges

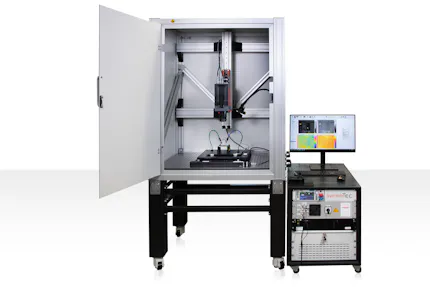

Configure Your Camera System

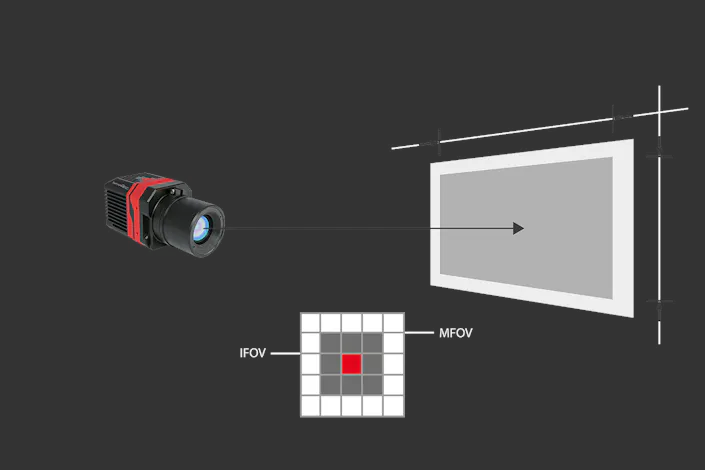

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Product Flyer

Get all the information you need at a glance in our product flyers