Infrared Thermography for Crane Rope Monitoring in Steelworks

Fully automatic 24/7 monitoring to detect weak points on crane ropes

Special tele-optics to detect smallest rope structures over long distances

Automatic warning and alarm when critical temperatures are reached on the rope

Precise measured values even under the most adverse environmental conditions

Steel production and processing are accompanied by numerous thermal processes. For quality assurance purposes, the temperatures of the steel itself are recorded and evaluated during production.

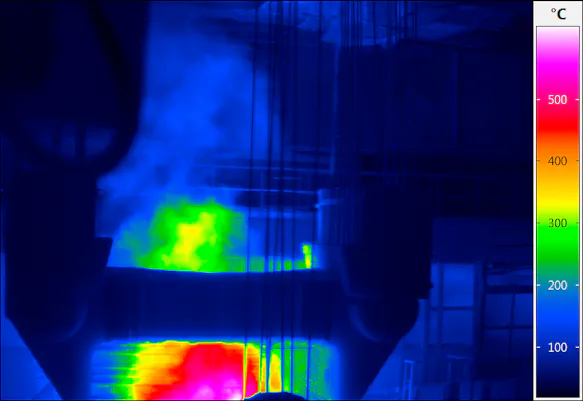

Careful attention must also be paid to the tools and equipment needed for production, including the cranes used to transport the ladles of pig iron. The crane ropes are exposed to great heat when filling the converter (charging). If the ropes become thermally overloaded and simultaneously subjected to strong mechanical stress, they can break, causing molten steel to leak into the production hall. In order to reliably eliminate the likelihood of such a disastrous scenario, a thermographic camera provides a continuous real time temperature measurement and threshold alarming. This allows the reliable early detection of weak points through non-contact monitoring of the temperature of the crane ropes.

Requirements for a thermographic system are very high in this environment. Thermal anomalies must be detected from a great distance despite dust and steam on the very small structures of the rope. Furthermore, the ropes themselves are in front of a hot background.

Camera Protective Housings

Get all the information you need at a glance in our product flyers

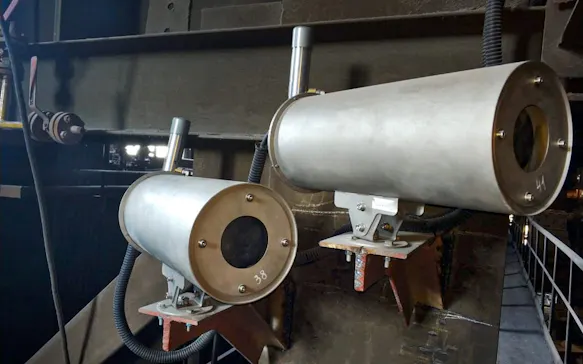

InfraTec provides a solution to this task with the VarioCAM® HD head. The camera is protected from adverse environmental conditions by a special protective housing with cooling and air purge and equipped with special tele-optics as well as an interface to the control system of the steelworks. Temperature measurement is carried out fully automatically with two cameras on each converter – one for monitoring directly during charging and one for a repeat inspection after this process.

The data is transmitted to the control system where it is displayed on a screen. If the pre-configured temperature thresholds are exceeded, an automatic warning is issued by the system and then, if necessary, an alarm is issued for each crane. The special software required was especially adapted for this process and its demands and is based on the INDU-SCAN 4.0 software from InfraTec.

Benefits of Thermographic Crane Rope Monitoring

Full automatic operation without stopping the crane

Monitoring and thermal characterisation of the crane rope even under difficult visibility conditions for the safe prevention of accidents or damage

High-resolution thermographic camera technology in a robust protective camera housing that protects against dirt and heat

Reliable alarm release at defined pre and main alarm limits

Customised system alignment and adjustment

Software for parameterisation, supervision, operation, display, evaluation and playback

Easy to operate data presentation in the steel plant network

Remote access available

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.