Thermography in Automotive Industry

Thermographic solutions for various fields of the automotive industry

Reconcile thermal behaviour of components with their standard behaviour

Non-destructive testing allows precise and efficient quality control

Integration into complex text solutions through interfaces to LabVIEW and MATLAB

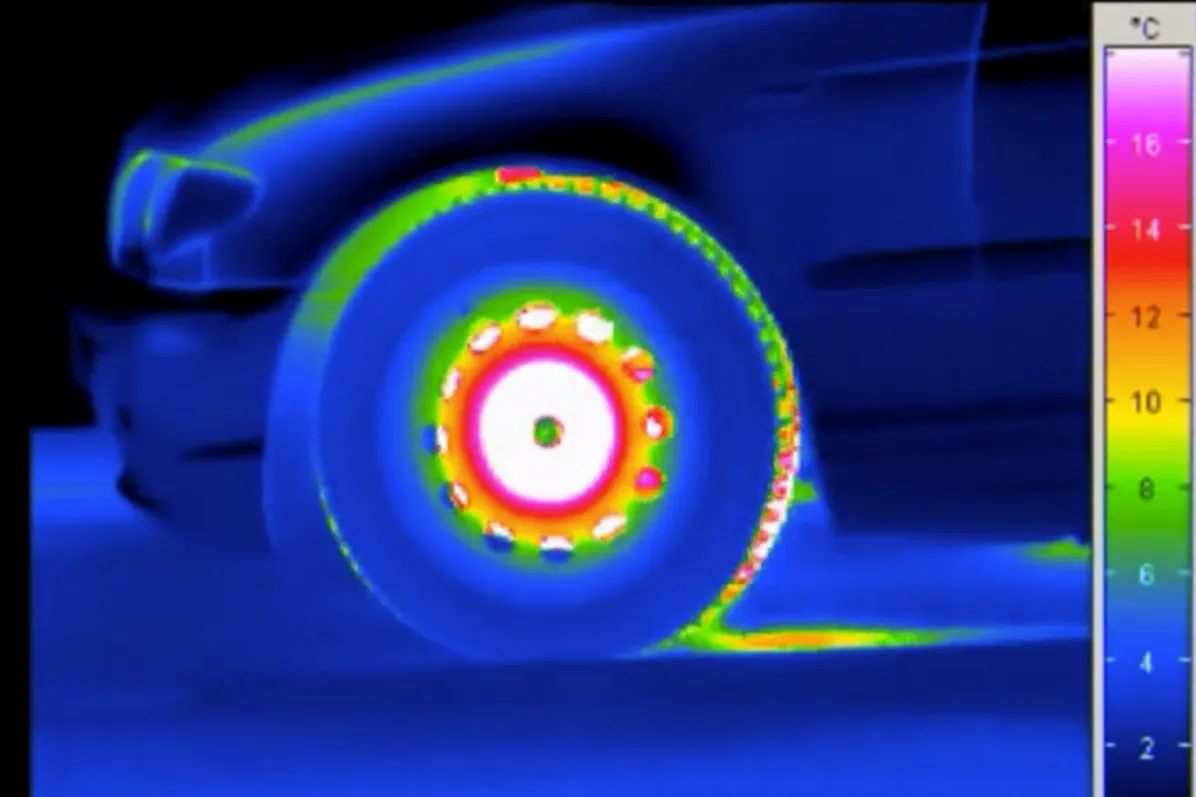

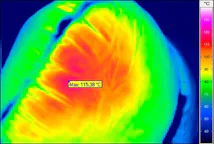

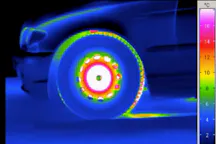

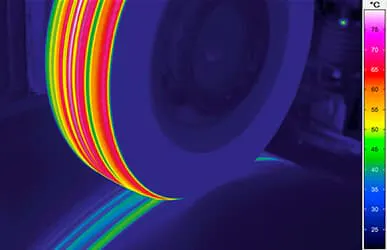

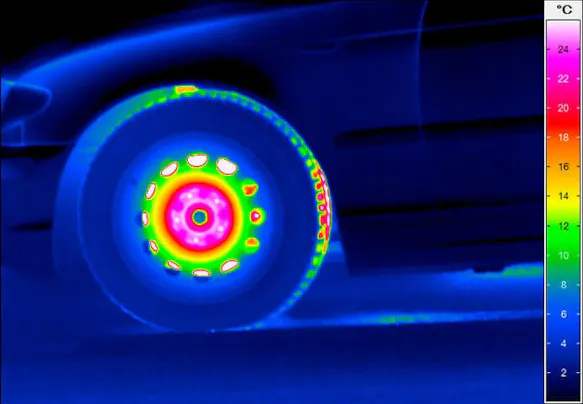

Analysis instruments for fast-rotating objects, such as tires or brakes

Non-Destructive Testing Saves Time and Money

The ultimate marketing tool for presenting cars’ safety are, certainly, crash tests - one of the worst testing methods for engineers and controllers since, in the course of this process, the device under test will be destroyed. Thus, neither further tests can be carried out nor is it possible to remedy any deficiencies of the product.

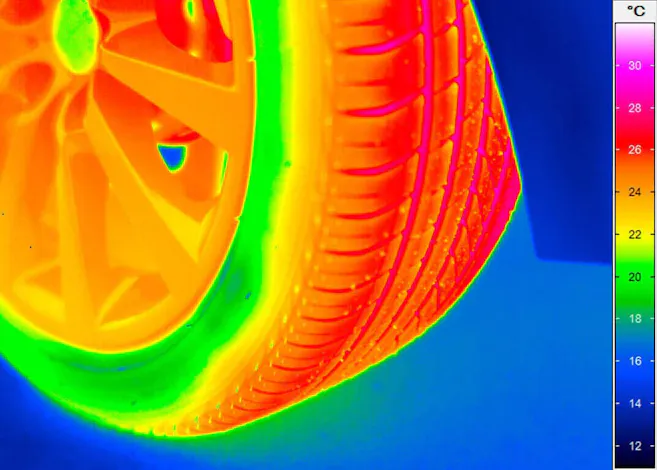

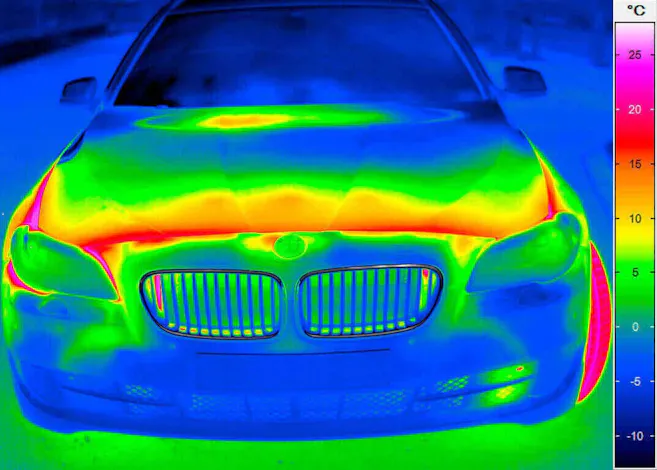

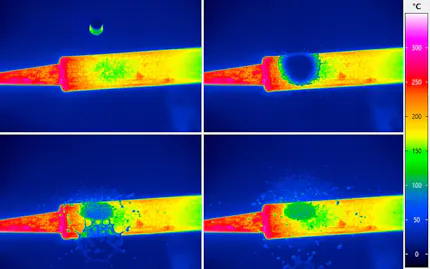

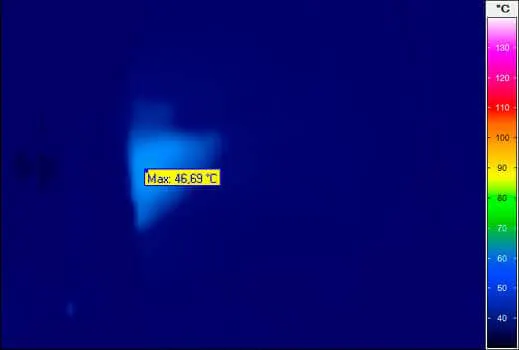

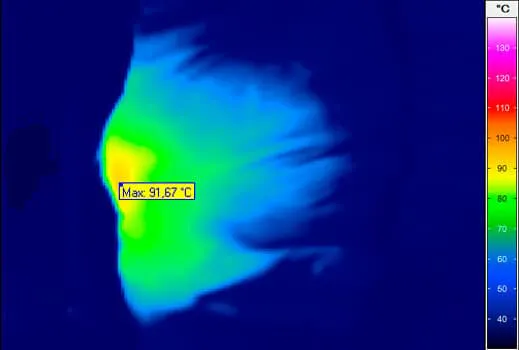

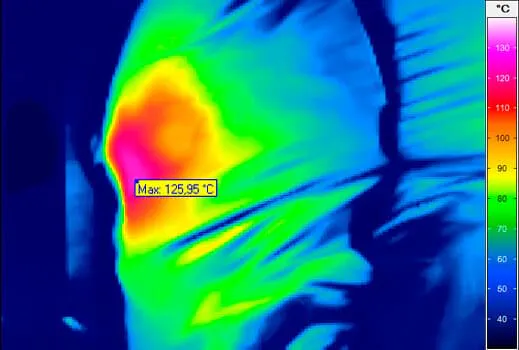

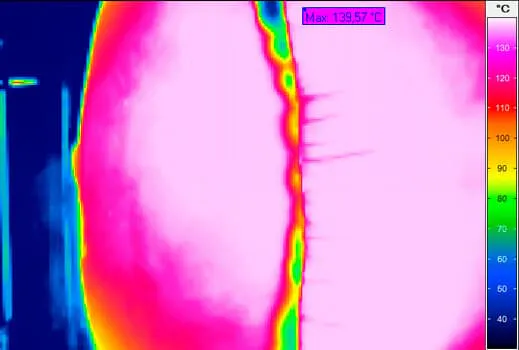

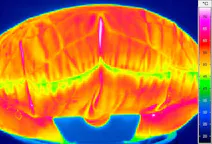

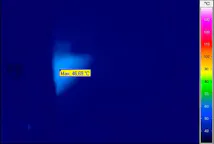

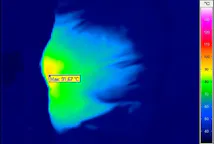

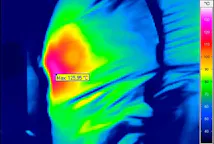

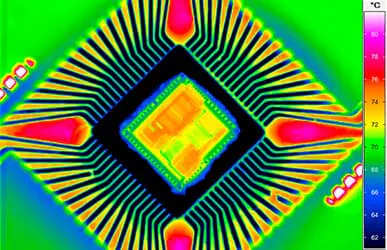

Thermal imaging helps to make defects visible without damaging the device under test on its testing. Therefore, functions of catalysts as well as electric systems of cars and motor assemblies can also be tested with the help of infrared camera systems.

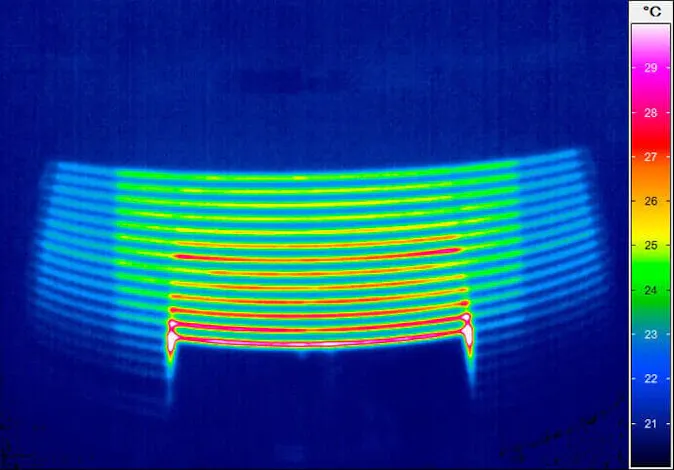

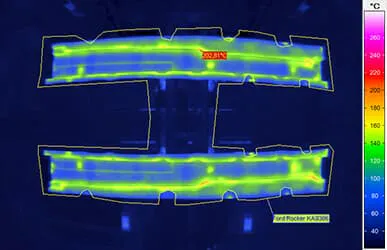

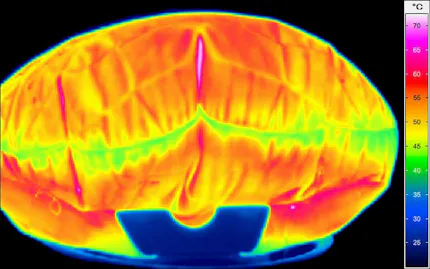

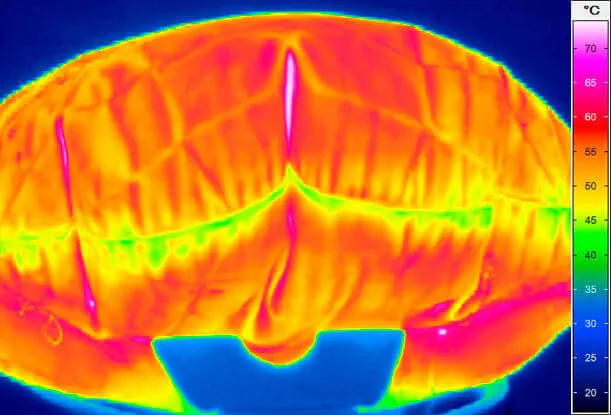

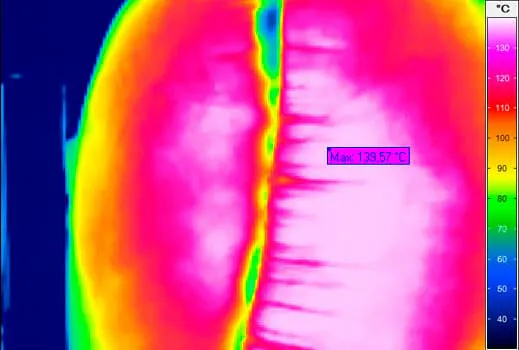

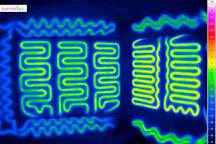

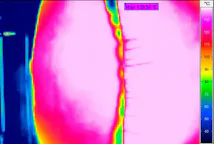

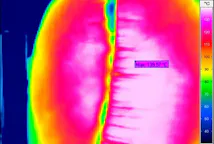

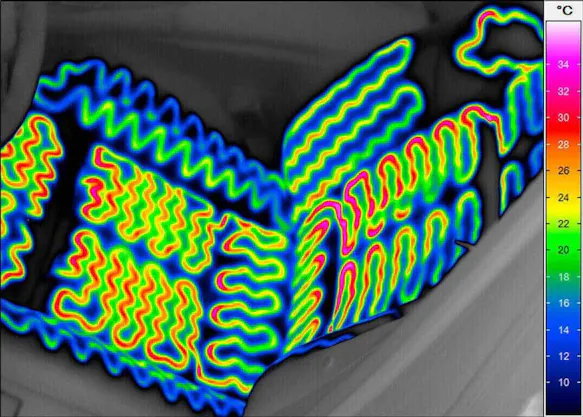

Moreover, defects and deficiencies of multiple products for the automotive industry are only to be detected through temperature changes. Thus, heated seats and window heating can be tried and tested for their functionality by applying infrared camera systems.

Integrate Thermographic Solutions by InfraTec

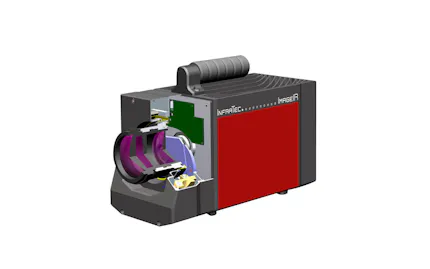

Based on a great number of applications, especially in the automotive sector, InfraTec integrates multiple requirements directly into infrared cameras, respectively into the software package IRBIS® 3. High thermal resolutions, fast frame rates and the integration of infrared camera systems into complex test environments within the scope of National Instruments LabVIEW are only a few examples.

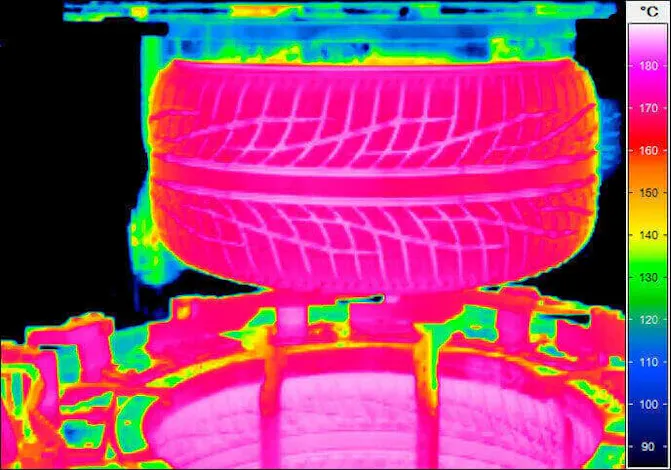

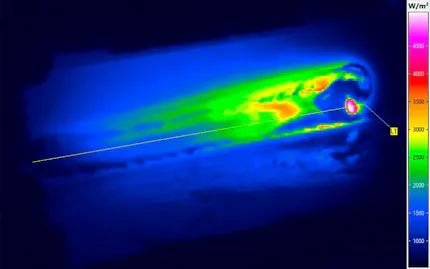

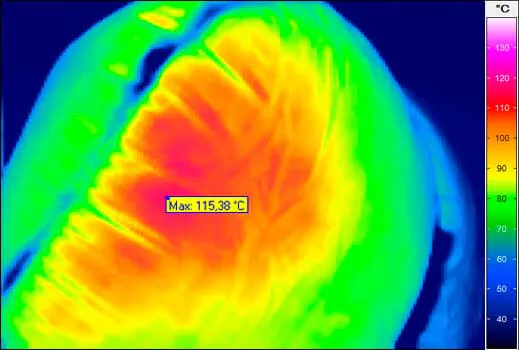

In order to test fast-rotating objects, such as brakes or tires, InfraTec has developed a special solution and software IRBIS® rotate. Thermal behaviour of diverse braking materials or specific forms of disc brakes can be analyzed at full speed with the help of the infrared camera series ImageIR®.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Product Flyer

Get all the information you need at a glance in our product flyers