High‐performance Full Optics

Selection of High‐performance Full Optics for Optimum Image Quantity

As in the professional photography sector, beside the camera sensors used, the quality of the IR lenses is also decisive in the thermography sector for the creation of precise and detailed thermograms. The lens is a significant component of a camera system and is a decisive factor in the creation of high‐quality images or thermograms.

Optical Criteria of Infrared Optics

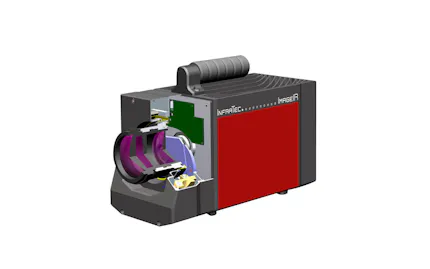

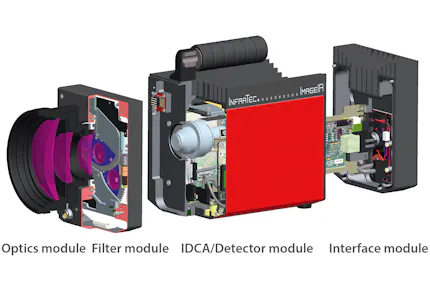

ImageIR® Features

Infrared Lenses for Camera Series ImageIR®

Complete Optical Assortment

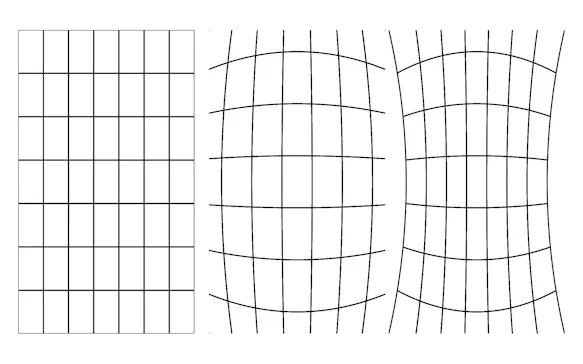

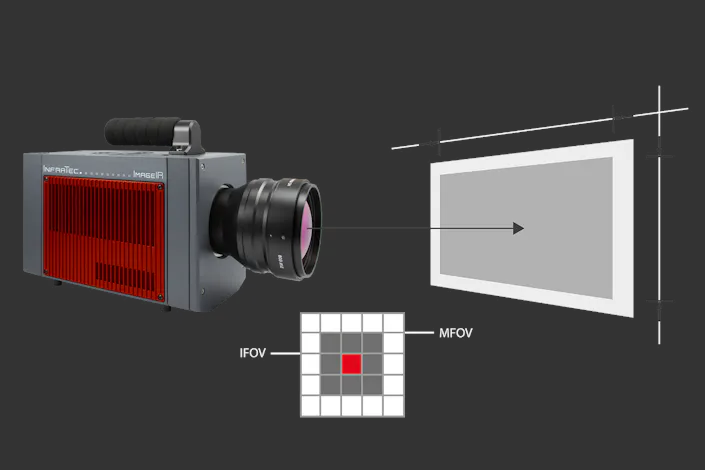

High quality precision lenses allow the adaptation of the image geometry to almost every measuring situation. Its performance parameters are calibrated with respect to functionality, quality and flexible application. Due to proper IR-transparent lens materials and high-precision antireflexion coating, the lenses are optimised for different spectral ranges. Additional macro accessory lenses reduce the working distance, increase the geometrical resolution and guarantee highest imaging quality.

Solid Immersion Lens (SIL) for ImageIR®

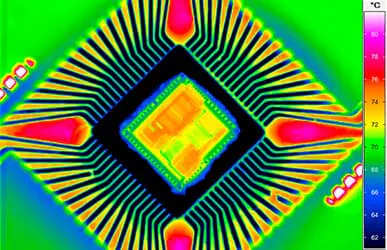

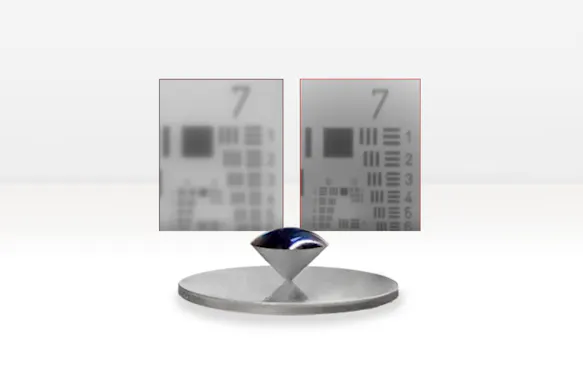

In order to make particularly small structures clearly visible, an infrared camera with a large detector format is suitable. In some cases, special measurement and testing tasks require a further increase in spatial resolution. In the field of micro-thermography, high-performance infrared microscopic lenses are used for this purpose. Their benefits can be further increased in conjunction with Solid Immersion Lenses (SIL). Mounted on the optics, these immersion media significantly improve the resolution of even the smallest structures in the µm range.

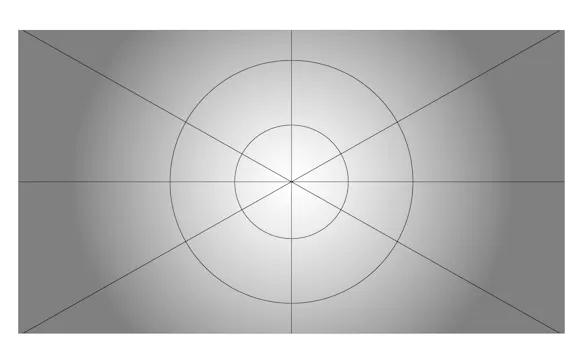

Precision Calibration & Lenses – Highest Accuracy

The multi-characteristic calibration algorithm developed by InfraTec is used to compensate the effect of fluctuations in ambient temperatures and enables great repeatability as well as optimum running-in behaviour of the system. In combination with thermally decoupled lenses a high image homogeneity and an excellent measurement accuracy with tolerances of 1% are achieved.

Motor Focus for ImageIR® Full Lenses – More Comfort

All interchangeable standard lens systems of the ImageIR® series can be combined with a motor focus unit, which is controlled by the camera operating software. It enables precise, remote and fast focusing. In addition, an autofocus function is available which operates reliably even with low image contrasts.

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

f/1.0 Precision Infrared Lenses

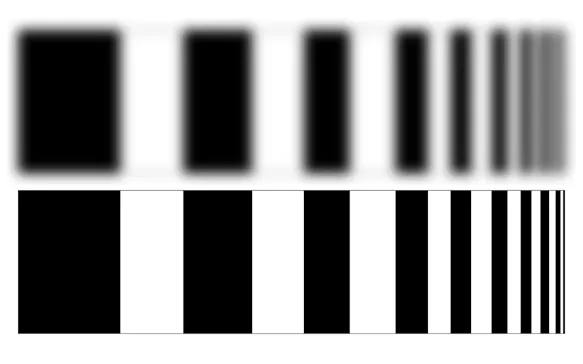

The f‐number f/1.0 precision infrared lenses, used for the uncooled camera series VarioCAM® High Definition, exhibit an extremely high IR transmission and prevent undesirable image inhomogeneities and imaging errors such as vignetting and distortion etc..

The quality of the lenses is an important criterion that contributes to adequate radiation reaching the detector, even in case of low lens temperatures, creating low‐noise images with reliable measured values. In this way, a high thermal resolution of 0.02 K is achieved, which results in outstanding image quality and detail accuracy. A comprehensive lens assortment covers the range of potential measured objects from micro‐thermography to telephoto applications for measuring objects at a great distance. The lenses of the VarioCAM® HD camera family are conceived as uncompromising complete lenses with the opening number 1.0, maximum transmission and transfer volume as well as minimum distortion.

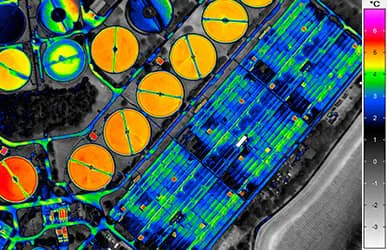

A special, highly resistant DLC (Diamond like carbon) coating protects the optically active surfaces of the lens even under harsh conditions. Extensive measuring objects such as photovoltaic systems can also be thermographically measured reliably and efficiently, such as objects requiring safety distances, as in the case of high‐voltage installations. When changing a lens, this is detected automatically by the camera and the stored calibration data is loaded.

Benefits of InfraTec Lenses at a Glance

High‐quality full optics with lens detection

F‐number f/1.0 for extremely high light intensity and signal exploitation, prevention of thermal aperture effects

Outstanding image quality

Multiple anti‐reflexion coatings for the optimisation of the transmission features

Athermalised lenses achieve a very high focus stability, even in case of severely fluctuating ambient temperatures

Comprehensive lens assortment (super wide‐angle, wide‐angle, tele, normal, microscopic lens and macro resolution) allows the flexible use of the camera

Long-range Thermal Zoom Cameras

To meet the versatile requirements, InfraTec develops thermal imaging zoom cameras in HD quality - with cooled and uncooled detectors. Their main specifications are:

ImageIR® 6300 Z

Cooled focal plane array photon detector operating in snapshot mode with (640 × 512) IR pixels

Standard built-in 7.5x zoom lens with motor focus

Zoom infrared camera series ImageIR® 6300 Z

ImageIR® 8300 Z

Cooled 640 x 512 IR pixel detector with a (28 … 850) mm lens

Field of view: (19.8 × 15.9)° ... (0.6 × 0.5)°

Super-zoom infrared camera series ImageIR® 8300 Z

ImageIR® 9300 Z

Cooled 640 x 512 IR pixel detector with a (28 … 850) mm lens

Field of view: (39.8 × 32.3)° ... (1.3 × 1.0)°

Super-Zoom Infrared Camera Series ImageIR® 9300 Z

VarioCAM® HD Z

Uncooled 1,024 x 768 IR pixel microbolometer detector with a (25 … 150) mm lens

Horizontal field of view: (41.5° @ 25 mm … 6.6° @ 150 mm)

Infrared camera series VarioCAM® HD Z security

Complete solutions from InfraTec are always based on the IROD infrared monitoring software. In addition, InfraTec cameras can be incorporated into the systems of external partners. This extends the possibilty to integrate ITAR-free thermal imaging cameras into various static platforms, ground vehicles, aircraft or ships.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.