Precise MN·m Torque Measurement in Wind Turbine Test Benches

The generation of electricity power produced by wind turbines is expanding worldwide. This development is associated directly with an increasing demand to test the product reliability, functionality and life durability of wind turbine subsystems like the drive train.

The generation of electricity power produced by wind turbines is expanding worldwide. This development is associated directly with an increasing demand to test the product reliability, functionality and life durability of wind turbine subsystems like the drive train.

To achieve feasible system test results, it is necessary to measure MN∙m (Meganewton meter) torque, one of the most important state variables of nacelle operation, traceably and with high precision according to national metrology institutes (NMI) standards. At the moment the torque measurement accuracy in the existing nacelle test benches lies in the range of 5 % referred to measured value and does not fulfil the requirements of NMIs and should be enhanced. To reduce the torque measurement uncertainty, it is important to identify and to quantify the specific influences on MN∙m torque measurement. Scientists at the Center for Wind Power Drives (CWD) of RWTH Aachen University are focusing on this task.

InfraTec Solution

RWTH Aachen University

Chair for Wind Power Drives (CWD)

Kock, S.; Jacobs, G.; Bosse, D.

www.cwd.rwth-aachen.de

Thermal imaging system:

VarioCAM® HD research

Influences on the MN∙m Torque Measurement

Besides rotational speed, the torque is one of the most important measurement parameters during the wind turbine test bench operation. A precise torque measurement is crucial for the quantification of the input power and the efficiency of subsystems (e.g. main bearing, gearbox and generator) and the entire drive train of the wind turbine. Furthermore, the measured torque is used for the investigation of the impact of the critical operation modes, such as start-up or emergency shut-down, on the local loads and the behavior of the entire system. In this way the torque measurement accuracy defines the result quality of the investigations on the wind turbine test bench.

Temperature counts among the ambient parameters, which have a crucial impact on the torque measurement. However, its influence is not investigated adequately for the wind turbine test benches at the moment.

Challenges of the Temperature Measurement

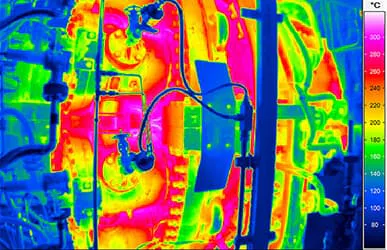

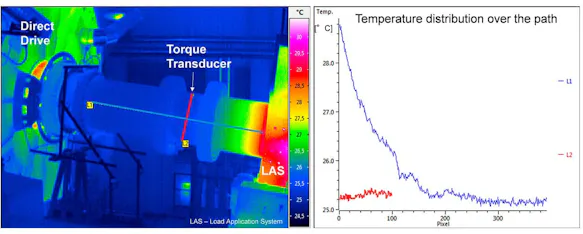

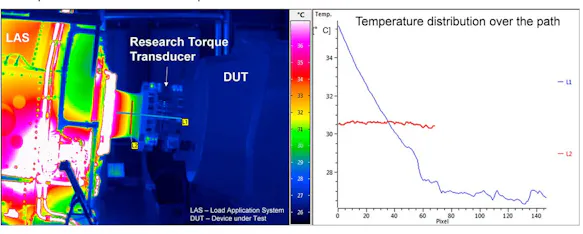

The wind turbine test benches comprises high amount of components, each of which is responsible for a heat input to the overall system, such as prime mover, hydraulic power units, load application system and electrical converter which contribute to the temperature fluctuations of the test bench shaft and torque transducers during the operation time. Moreover, these heat sources can lead to an inhomogeneous temperature distribution and thus decrease the torque measurement accuracy.

For the quantification of the influence of the temperature on the MN∙m torque measurement accuracy it is important to measure the temperature of the entire transducer surface and not of a single measurement point. For this reason the standard approach of the temperature measurement by Pt 100 elements is not suitable. Their use requires the deployment of the telemetry and amplifier system what would make the measurements more complex and sensitive to errors.

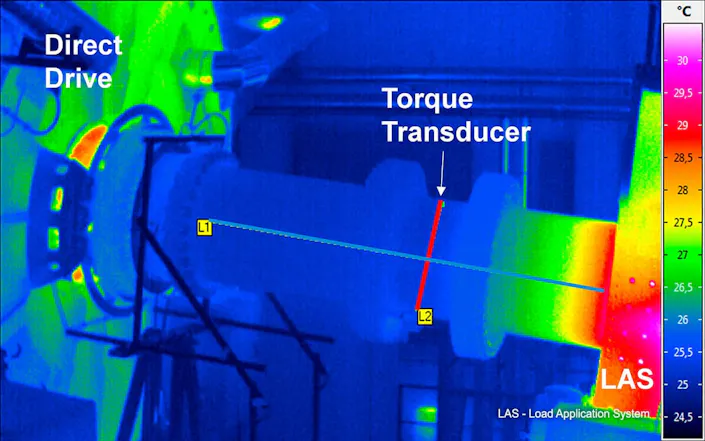

Instead, the CWD uses the thermographic camera VarioCAM® High Definition from InfraTec. It is a perfect tool regarding the flexibility, time and cost effort, ease of operation, result processing as well as measurement accuracy and reliability for the determination of the temperature distribution of the entire torque transducer and test bench drive train during the operation. This camera allows to measure simultaneously the temperature of the entire drive train by usage of a 15 mm wide-angle lens. Based on the knowledge of temperature distribution CWD employees quantify the influence of the temperature on the MN∙m torque measurement and subsequently indicate the measured MN∙m torque with higher accuracy.

Objectives of the Temperature Measurement

Temperature measurement can provide scientists with detailed information in terms of the following research matters:

How does the global temperature distribution of transducers look like?

Is the level of the temperature distribution homogenous or can hot-spots be detected?

What is the range of the temperature change during the full-load operation?

How can the cooling and heating process of the entire drive train be characterized?

The 4 Megawatt RWTH Aachen University Wind Turbine Test Bench

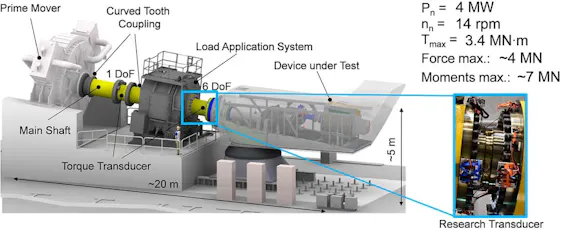

The CWD nacelle test bench comprises a prime mover for torque generation, a non-torque load application system for the generation of external forces and bending moments, device under test and an electrical power supply equipment.

The torque generation is realized with a low-speed direct drive. The generation of the external forces and bending moments is realized by hydraulic actuators. Using the example of the 4 Megawatt RWTH Aachen University nacelle test bench, it is possible to apply 3.4 MN·m torque under maximum bending moments of about 7 MN·m, 3.3 MN radial forces and 4.0 MN thrust. The rotational speed of the main shaft can be up to 30 min-1.

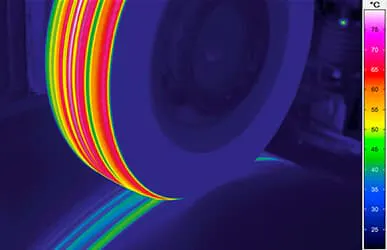

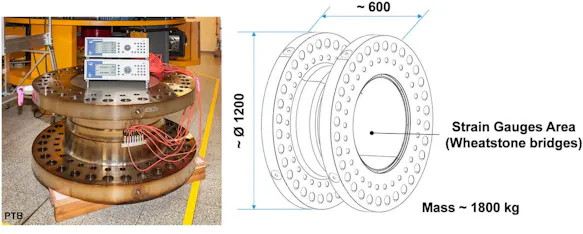

In most cases torque measurement in the wind turbine test benches is carried out under rotation. Thus the torque can be determined by using the transducer which is based on the strain gauges technology (Fig. 2). Such type of the transducer can react sensible to the high temperature fluctuations and unequal temperature distribution. After several hours of testing under full load the local temperature of the test bench components typically varies within a range of 30 K and achieves values up to 70 °C.

Exact Temperature Measurement to Determine the Influence of the Torque

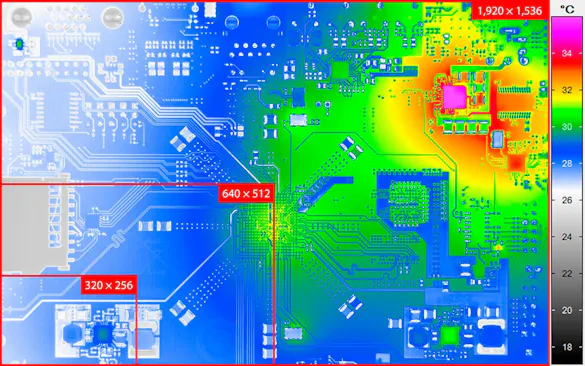

The CWD uses the VarioCAM® High Definition to determine the temperature distribution. Due to its geometrical resolution of 1.23 Megapixels, the precise detection of smallest temperature differences down to 20 mK and its high measurement accuracy of ± 1 % the thermographic camera provides the best prerequisites for analysing the thermal processes of an operating drive train of a wind turbine.

The preferred measurement frequency during torque calibration of the 4 Megawatt RWTH Aachen University nacelle test bench is 1 Hz. The scientists measure the temperature under different operation conditions of the test bench and as long-term measurements lasting up to 10 hours to investigate the cooling and heating process of the drive train. For this purpose, the VarioCAM® High Definition is positioned on different locations. Thus, the temperature distribution of the 5 MN∙m torque sensor of the Physikalisch-Technische Bundesanstalt, the National Metrology Institute of Germany, as well as that of the test bench torque transducer can be measured separately. Validation of the thermal imaging with Pt 100 elements is used to adjust the value of the emission factor.

The investigations of the CWD show that the increase of the temperature of the torque transducers after the full-load operation of 10 hours is in the range of 4 K. This measured increase in temperature serves as an initial point to optimize the available simulation models by adjusting the material properties of the transducer and strain gauge factors. Based on this, the measurement uncertainty of the torque can be quantified more precisely.

Equally important for the researchers is the finding that the global and local temperature distribution of the transducers remains constant during test bench operation. The temperature of the transducers in the strain gauge area fluctuates in the range 200 mK. This small inequality and fluctuation can be neglected.

The CWD can quantify the influence of the temperature on the torque measurement on the basis of all measurements with the VarioCAM® High Definition and its results. The influence is less than 0.01 % and is in the same range as the measurement uncertainty of the amplifiers of the torque transducer.

VarioCAM® HD research 700 Makes an Important Contribution to the Optimization of Wind Turbines

The VarioCAM® HD research 700 contributed to a better understanding of the temperature influence on the MN∙m torque measurement in wind turbine test benches by precise measurement of the temperature distribution in the drive train. The temperature distribution of the torque transducer remains constant, the fluctuation is less than 200 mK. This means that the inner strain gauge circuit can compensate the increase of temperature during the operation time. The increase of temperature during 10 hours full-load operation is in the range of 4 K. This results in a maximal uncertainty of less than 0.01 %. Analysis like this play an important role regarding the further improvement of the performance of wind turbines and international efforts to reduce greenhouse gas emissions.