High-Speed Thermography

Infrared camera systems allow thermographic precision at highest speeds

Snapshot detectors and complementary components provide for highest measurement speed

High availability also with fastest data acquisition and handling large amounts of data

Thermal behaviour of fast turning objects can be analysed

Special Components Provide High Frame Rate of Infrared Cameras

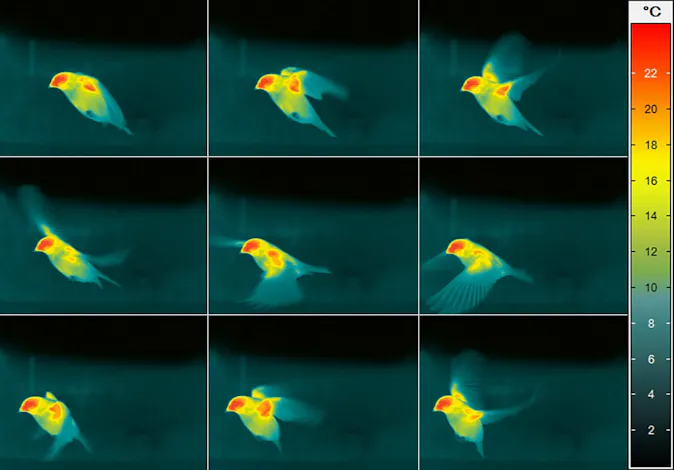

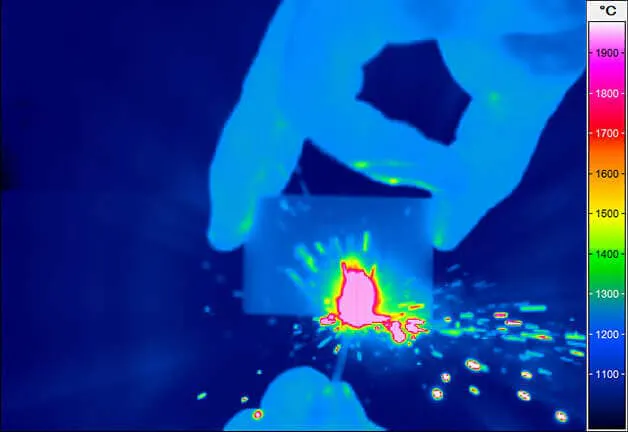

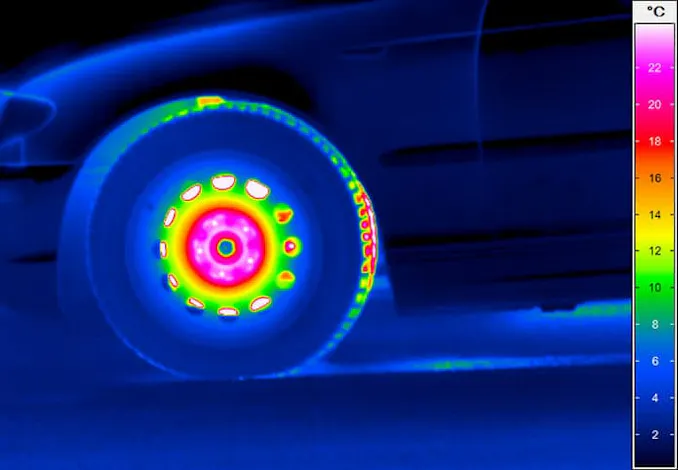

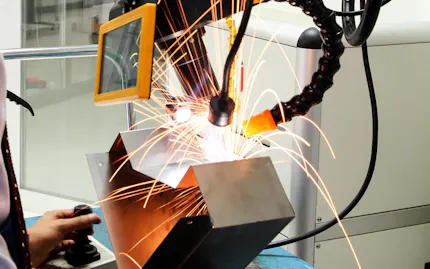

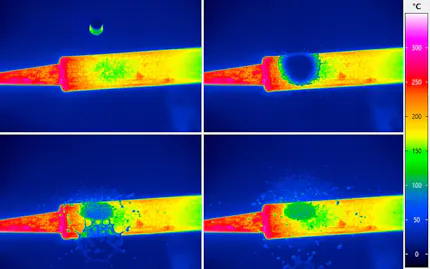

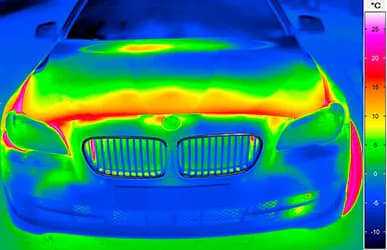

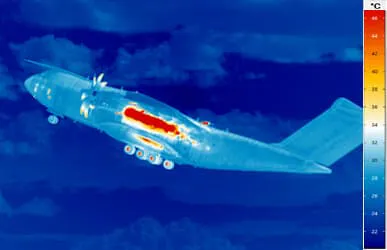

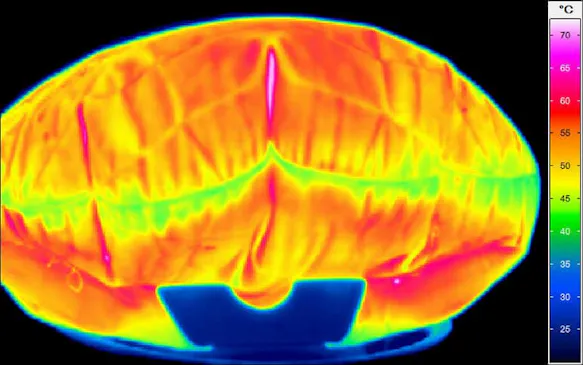

Fast infrared camera systems with a frame rate ranging up to some kHz open thermography doors to new applications. The thermal behaviour of high speed processes can be monitored and analysed. An example is the optimisation of airbags as the heat distribution during the explosion can well be analysed.

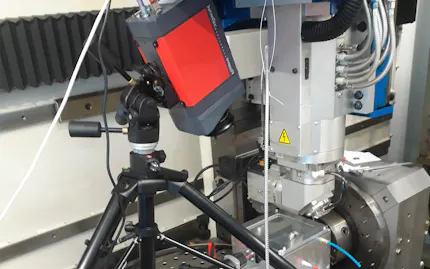

High-speed thermography with frame rates of more than 100 kHz are based on special detectors and acquisition units. Especially their ability to acquire and read out data in parallel provides thermographic measurements precisely in a millisecond range. Those detectors are so-called snapshot detectors which are integrated by InfraTec in their ImageIR® infrared camera series.

High-speed Thermography in Highest Quality

Introduction to the physical basics of thermal imaging

Special features and the potential of high-speed thermal imaging

Presentation of technical solutions and InfraTec camera models

Explanation of important parameters and their influence on thermal imaging

Presentation of various functions to adapt your camera to the application requirements

Flexible Software for Fast Acquisition and Analysis of Thermographic Data

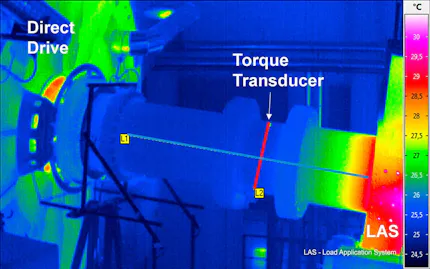

Detector and read-out unit of the infrared camera are one part to be well compatible. The second part is the communication of the infrared camera and the computer by which the infrared camera will be controlled and temperature data will be acquired. InfraTec provides flexible and highly available solutions which cater for the most different customer needs. The acquisition and analysis software IRBIS® 3 is well made for handling high-speed thermography and the analysis of large amounts of data.

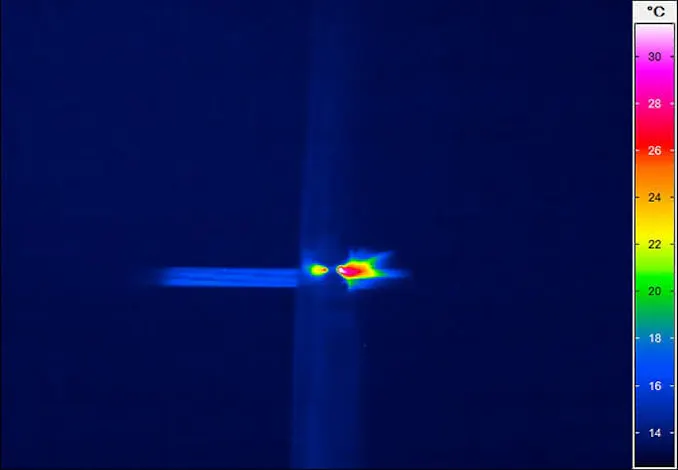

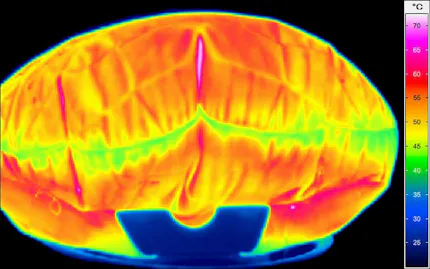

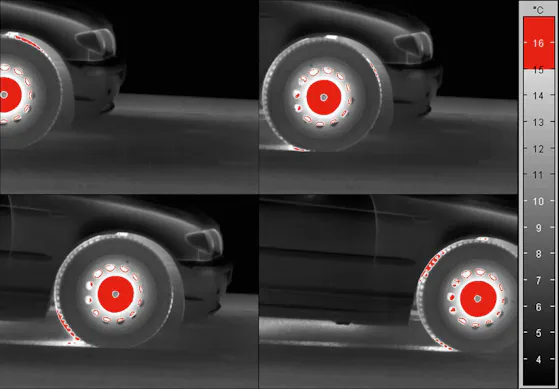

Besides its flexible standard solutions for high-speed thermography InfraTec also offers automated solutions for the thermal analysis of fast rotating objects. Using the software IRBIS® rotate tests of brake disks or tires can be thermally analysed.

Product Flyer

Get all the information you need at a glance in our product flyers