HDR Function

Enables Gapless and Error-Free Thermography of Objects with Extremely Large Temperature Gradients and Temperature Changes

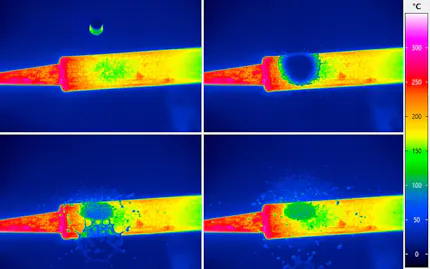

When measurement objects experience temperature changes of several hundred Kelvin within a very short time, thermography becomes a challenge. After all, neutral density filters have to be changed very quickly, for example by means of a filter wheel, in order to avoid measurement errors due to understeering or drive into saturation. A conventional solution comes up against its limits. Therefore, InfraTec has developed the High Dynamic Range (HDR) function for the infrared camera series ImageIR®. Thus you master the error-free and uninterrupted measurement of highly dynamic thermal processes.

HDR Mode Overview

Fast filter wheel with up to six positions for maximum flexibility for demanding measuring tasks

After selecting a calibration range, automatic start of the filter wheel revolution and composition of the thermogram

Wide single measurement ranges with spans selectable up to 1,500 K

Fullframe recording with (640 × 512) IR pixels and an IR frame rate of 350 Hz (ImageIR® 8300 hp)

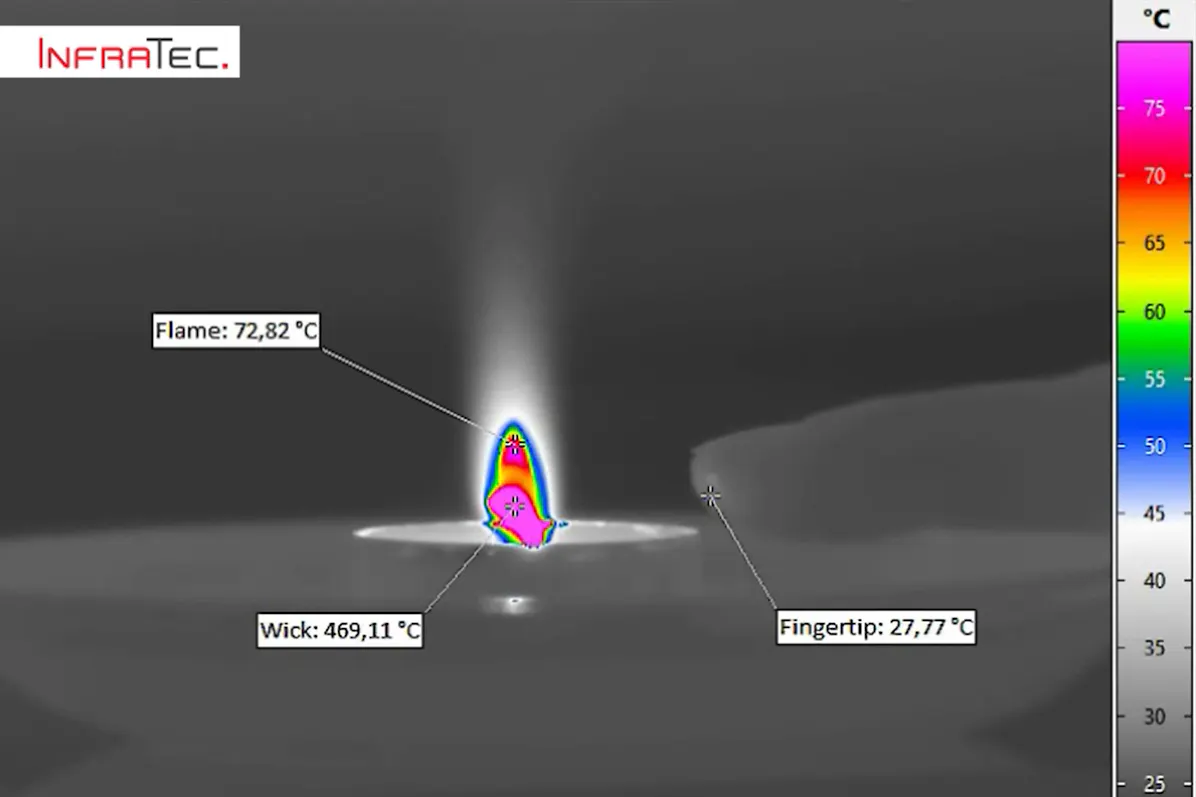

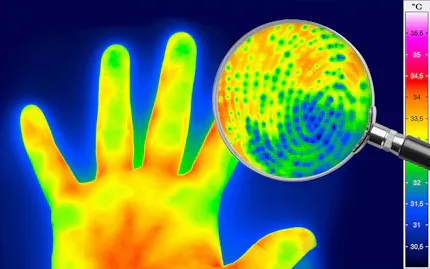

Challenges in Measuring High Temperatures

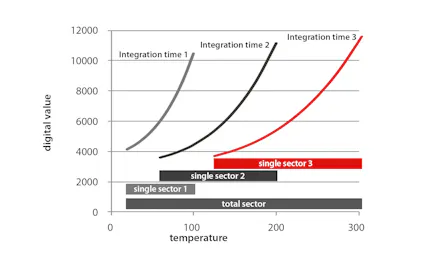

If very high temperatures are to be measured with an infrared camera, it must be taken into account that – for physical reasons – high intensities of infrared radiation occur. These can temporarily or permanently deteriorate the properties of the camera's detector pixels to such an extent that the temperature measurement is severely distorted or even the pixels are irreparably damaged. To attenuate these excessively high intensities, special neutral density filters are therefore placed in front of the camera's detector. They allow measurements on hot objects up to the upper end of the temperature measurement range, depending on the attenuation of the filter. At the same time, however, they also limit the usable temperature measurement range downwards. To measure temperatures in a very wide temperature measurement range, it is therefore necessary to change neutral density filters with different – but overlapping – usable temperature measurement ranges.

This is usually done in stages and the neutral density filters are changed for each individual measurement range. HDR eliminates the need to interrupt measurements to change filters. The function allows continuous recording of measurement scenarios with extremely varying temperatures and thermal analysis of targets that experience extremely rapid temperature changes over a very wide range. HDR therefore enables error-free thermographic recordings even with large temperature differences and changes.

Download HDR White Paper

Download the HDR white paper to get further information how it works and what the benefits are.

How HDR Works

The starting point of the HDR function is the ability to switch between individual images using neutral density filters, even at high frame rates. This is implemented in the ImageIR® series with a fast filter wheel. Designed for such tasks, it rotates at more than 5,000 revolutions per minute. With up to six filter positions, the wheel offers maximum flexibility to adapt the camera measurement ranges to the respective measurement task. When recording in HDR mode, several thermograms with different integration times and different filters are recorded very quickly one after the other and combined to form an overall image with a high dynamic range.

To activate the HDR function, it is sufficient to select a previously defined calibration range. Then the rotation of the filter wheel and the assembly of the thermogram starts automatically. The measurement range can cover a span of up to 1,500 K. The frame rate of the camera is synchronous to the rotation speed of the wheel and can reach up to 350 Hz using ImageIR® 8300 hp.

A separate integration time and corresponding temperature calibration is stored for each position of the individual neutral density filters. The filters attenuate the signal of the measured objects in the desired temperature range, which reliably avoids interference effects. In this way, users obtain precise measurement results and highly dynamic images over a very wide temperature range.

Camera Series ImageIR® 8300 hp

Large detector enables highest sensivity

(1,280 × 1,024) IR pixels by genuine camera hardware

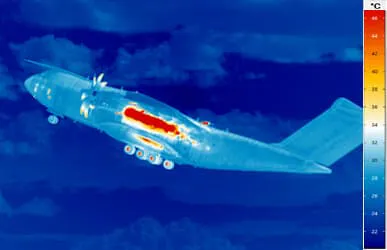

Analysis of extreme temperature changes and gradients in full frame

Highly accurate and repeatable measurements

High-speed, long-distance interference proof data transmission

Flexible setting of temperature measurement ranges/integration times beyond calibration ranges

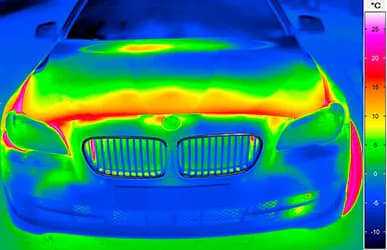

Facilitates the analysis of objects with extreme temperature gradients