Investment-secure Testing Procedure at Volkswagen

The Department of Quality Assurance for Joining Technology in Car Body Construction at Volkswagen Sachsen GmbH's plant in Zwickau and InfraTec have jointly developed a test procedure for laser weld seams on car body parts and have been using it successfully in practice for several years. When electric vehicles went into production, the joining process was replaced by resistance spot welding. The INDU-SCAN test bench already in operation was converted using existing technology and modernised with intelligent algorithms and robot technology to enable quality control of the joined sheet metal parts. Following a successful pilot phase, the technology is now in series production for electric cars at the Zwickau vehicle plant.

Long Years of Cooperation in Quality Assurance

InfraTec and Volkswagen Sachsen have been working together since 2007 on non-destructive methods for quality assurance in car body construction. Supported by other partners, the two companies built a test station for thermographic quality control of laser welds. In 2018, VW began converting its plant in Zwickau-Mosel to produce a new generation of electric cars based on the ‘modular electric drive kit’. In this context, the decision was made to no longer weld the body parts of battery-electric vehicles using lasers but instead using the resistance spot welding process. This raised the question of whether the existing thermal imaging system could continue to be used as part of an INDU-SCAN solution.

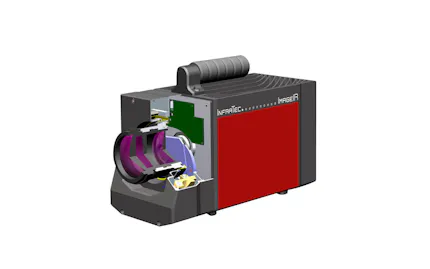

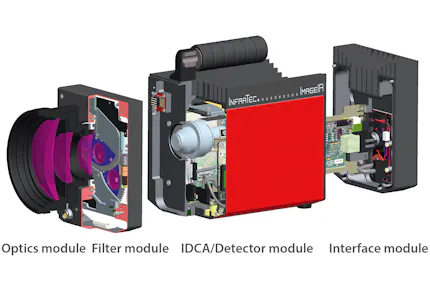

The experts from VW and InfraTec then worked together to modernise the existing thermography testing system, which had been designed for quality assurance in laser welding. For this purpose, the system was equipped with new state-of-the-art components, and the flash unit was adapted to the changed requirements. This includes, for example, the more powerful ImageIR® 8300 hp infrared camera. In addition, intelligent algorithms were integrated to evaluate the enormous amounts of data generated by the increasingly complex thermograms.

InfraTec Solution

Volkswagen Sachsen GmbH

Quality assurance in joining technology for car body construction

Vehicle plant, Zwickau

www.volkswagen-sachsen.de

Automation solution / Thermal imaging system:

INDU-SCAN / ImageIR® 8300 hp infrared camera

Active Thermography in Automotive Production

An earlier application report from the Volkswagen Zwickau plant shows how active thermography has already been successfully used for non-destructive quality assurance of components, including automated evaluation and reliable documentation of inspection results.

Active Thermography Monitors Joint Quality

In resistance spot welding, two electrodes are pressed onto the car body parts to be joined with high force from both sides and electrical energy with a current of several thousand amps is fed into the steel. Due to the ohmic resistance that the metal opposes to the flow of current, heat is generated, which melts the metal at the contact points in a lens shape. When the electrodes are removed, this lens cools down after a few seconds and the sheets are joined together at the points.

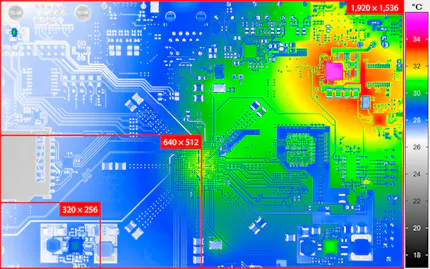

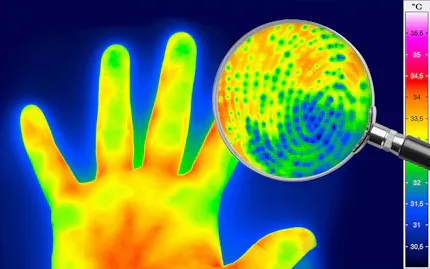

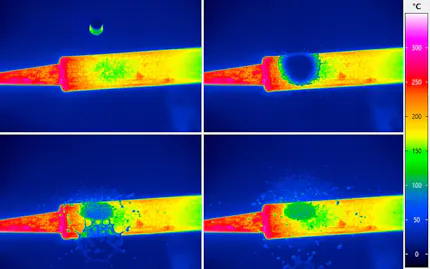

Active thermographic quality testing of the joint is performed in transmissive mode: The thermal energy introduced into the workpiece by flash excitation is transported through the material by heat conduction and the temperature on the opposite side of the joined car body panels is measured. Pixel by pixel, the infrared camera determines the heat distribution curves for the flat weld spot.

The connection quality of the spot weld is guaranteed if the temperature is above a predefined threshold value at a specified evaluation time. Specially developed software then provides the most uniform image possible of the weld spot. Its boundaries are clearly visible in the display, as are inclusions, impurities and other defects.

Measuring Unit with Industrial Robots

To test entire vehicles using this method, the INDU-SCAN measuring station was equipped with two industrial robots that can be positioned on traversing axes. An infrared camera is attached to the freely movable arm of one robot, and the flash head is attached to the arm of the other. The generator required to produce the flash travels on the foot of the second robot.

“This is the world's first thermographic solution for testing resistance weld spots in large-scale automotive production in an automated, contact-free manner,” estimates the head of quality assurance in vehicle manufacturing. The new technology, he says, is four times faster, but also more ergonomic and effective than previous testing methods for such weld spots. “This is a minor revolution for the industry.”

INDU-SCAN Beats Ultrasound

The highly automated, thermographic quality assurance of the weld points is in many respects significantly superior to the manual ultrasonic testing previously used in car body construction. The latter can only be carried out at random and is often strenuous, as the testers must work overhead again and again. Attempts to automate ultrasonic testing have repeatedly failed in the past.

Moreover, the INDU-SCAN solution is significantly faster: Whereas ultrasonic testers usually needed 30 to 40 seconds to manually analyse a weld spot, the thermal imaging inspection station only needs five to ten seconds for each weld spot analysed. This means that around 1,500 weld spots can be inspected per shift instead of only 500 to 600. That, in turn, allows for more random samples, ensures consistently high quality, and gives production plant operators the chance to take corrective action in good time if problems arise in production.

Focus on Further Development

The quality assurance process developed by VW and InfraTec can be used not only for electric car production, but in any factory that uses resistance spot welding. Together with InfraTec, the experts in Zwickau want to further improve and accelerate the new process. Their goal is an ‘inline’ solution in which random samples are no longer taken at delayed intervals, but instead the quality of the weld spots is assessed in real time during ongoing car production.