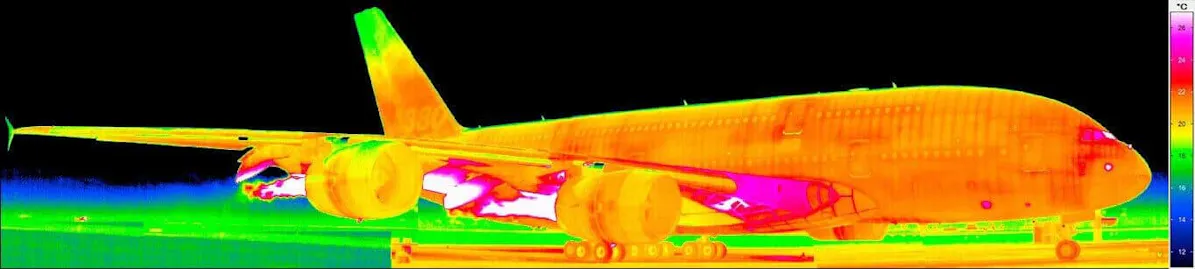

Thermography in Aerospace Industry

Solutions for aerospace through thermal imaging

Highest demands on thermal resolutions for safety standards

High-speed data acquisition supports monitoring and controlling of fast processes

Active heat flow thermography allows testing of modern composite materials and lightweight construction elements

Non-destructive material testing reduces expenses of quality control

Aerospace Sets Highest Demands on Infrared Camera Systems

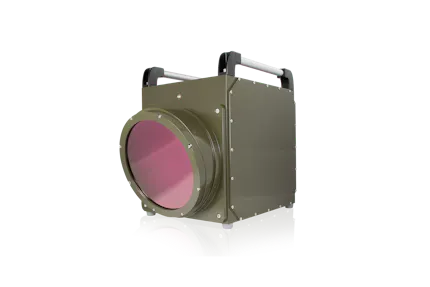

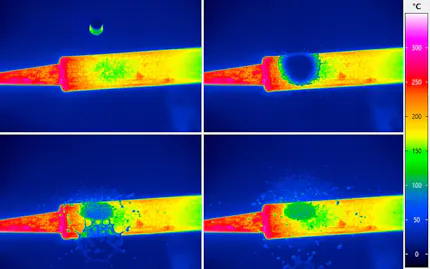

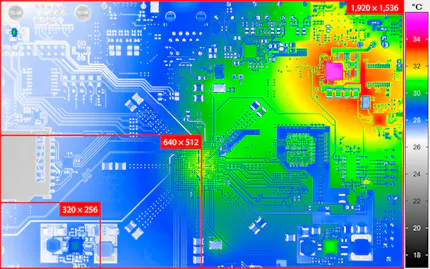

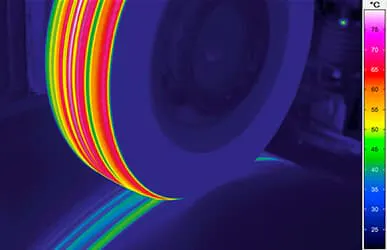

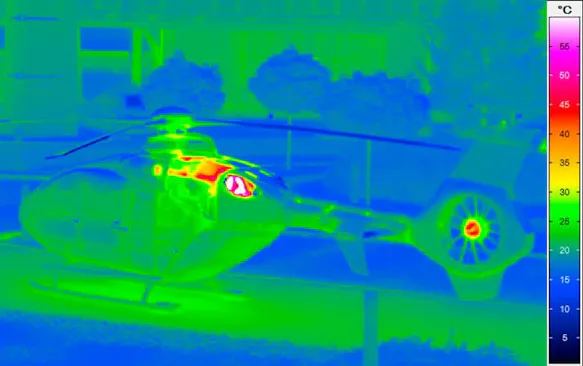

Measurement tasks of the aerospace industry often require infrared cameras with very high thermal resolutions of 20 mk and/or high frame rate of 100 Hz and more. Thus, for instance, accurate analyses of aero engine’s thermal behaviour are due to high safety and reliability requirements of the aviation authority. Moreover, quality controls of fuselages, wings and rotor blades of aeroplanes, respectively helicopters, can be carried out in form of efficient fault analyses with infrared camera systems.

Live Online Events 2026

Active Heat Flow Thermography for Testing Composite Materials

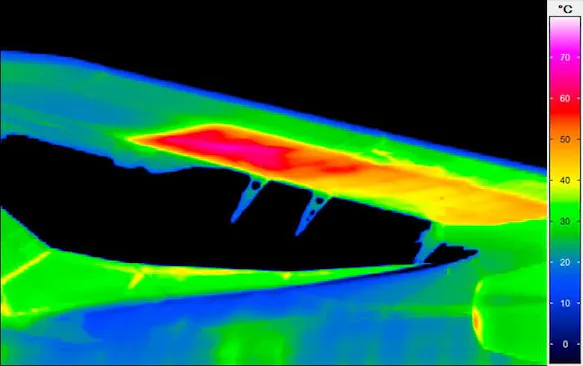

In particular, the application of light and robust composite materials and other lightweight construction processes of the aerospace industry requires an accurate quality control. For this purpose, active heat flow thermography is increasingly used for the production. Various activation and analysis systems allow efficient fault analyses with fast and high-resolution infrared cameras, even inside materials or the construction.

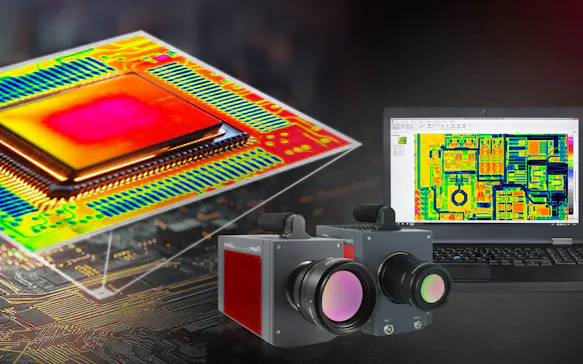

Infrared Cameras by InfraTec Solve Customer Problems

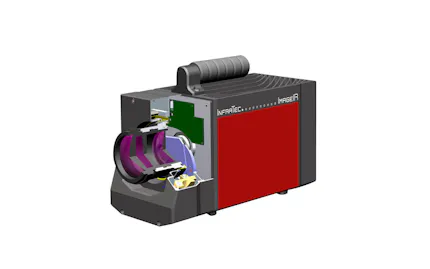

Due to its thermography solutions, InfraTec was able to acquire customers, such as the German Aerospace Center or the European Aeronautic Defence and Space Company (EADS). Contributions to this were high thermal resolutions of the infrared camera series VarioCAM® and the high-end camera series ImageIR®.

Moreover, ImageIR® infrared camera systems can reach a remarkable speed of more than 10 KHz forming the basis of certain process analyses. Apart from the quality of infrared camera systems, engineers have been coping with another great challenge - the cameras’ integration. Thus, clients benefit from customized and optimally integrated solutions which the modern and efficient thermographic software IRBIS® 3 is also part of.

Online Events on Demand

Flow Analysis Using Thermal Imaging

General information about infrared thermography and presentation of different infrared camera techniques

Presentation of different flow types and how to measure them with thermography

Demonstration of different application possibilities, e.g.: aerodynamic optimisation, heat management industry, environmental research, geological research

Technical lecture “A Non-Intrusive Particle Temperature Extraction Methodology Using Infrared and Visible-Image Sequences for High-Temperature Particle Plumes”, Jesus D. Ortega, PhD, MSME, MBA / Anderson School of Business and School of Engineering, The University of New Mexico, USA

Thermography for Industrial Automation

Efficient quality control through fast, contactless temperature measurement during ongoing production

Flexible system solutions from modular components to fully customized turnkey setups

Integrated software for automated evaluation, documentation, and triggering of follow-up processes

Efficient Material Testing – Non-destructive and Contactless

Theoretical background – mechanical force, stress and temperature Methods for analysis

Examples from practice with application samples – elastic periodical load test and fatigue test

Short overview about InfraTec products

Complementary technical lecture

"Contribution of Thermoelastic Stress Analysis in mechanics of materials and structures: some illustrations" from Prof. Vincent Le Saux, École Nationale Supérieure de Techniques Avancées Bretagne

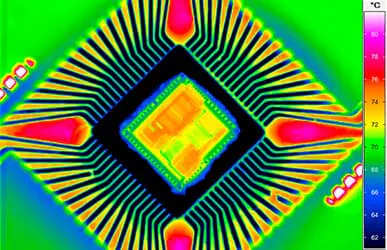

Micro-Thermography – Contactless Temperature Measurement in the Micrometer Scale

What are the physical characteristics of micro-thermography?

What are the technical requirements for an IR camera system?

Which selection criteria are important and relevant?

In which application areas is micro-thermography used?

Spectral Thermography – Basics and Applications

General information about infrared thermography and InfraTec

Definition of spectral thermography

Advantages and challenges of spectral thermography

Specific camera system requirements for spectral thermography

Further Events on Demand Webinars

In addition, further on-demand webinars on thermography in the aerospace industry offer in-depth information on specific applications and solutions. Take a look at the following webinars.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.