VarioCAM® HDx head Lock-in

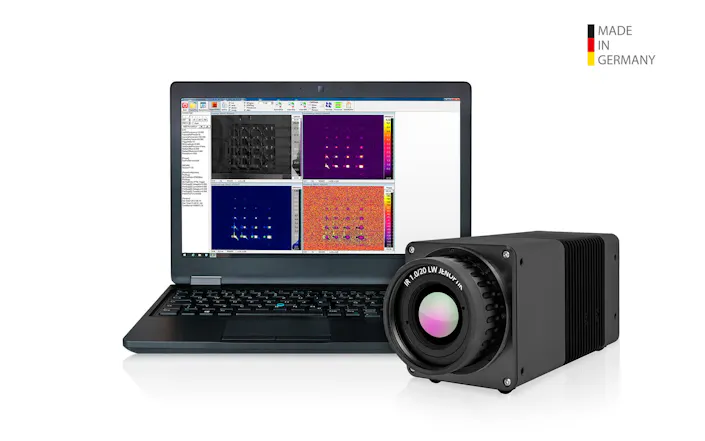

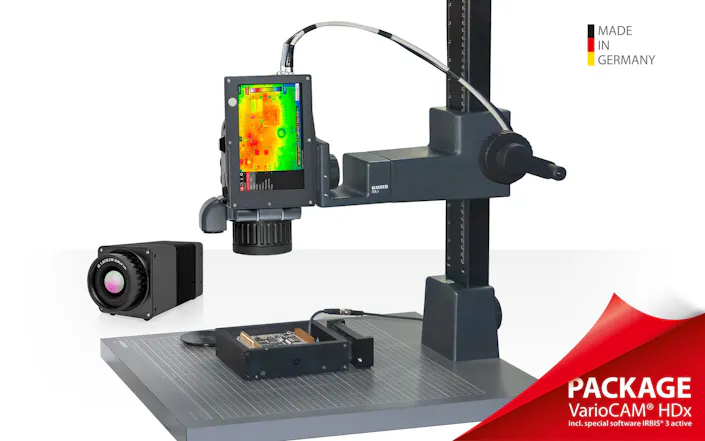

For professional measurement tasks using Lock-in Thermography, InfraTec offers a complete package including the stationary VarioCAM® HDx head thermographic camera, IRBIS® 3 active thermography software, trigger unit and accessories.

Expert Package for Research and Development

Depict structures with a pixel size up to 17 μm

Extensive selection of interchangeable lenses to adapt the camera to different requirements, such as object size and required working distance

GigE interface to transmit very detailed images in real time

Modular design to ensure maximum flexibility

Powerful Package for Lock-in Thermography from InfraTec

Microbolometer detector with (640 × 480) IR pixels

System integration via LabVIEW or MATLAB interfaces, SDK

Special software IRBIS® 3 active

Automatic processing of data quantities

Real-time data connection via GigE-Interface

Microscopic lens with up to 17 µm pixel size

Quadrupling the image format to depict thermally the measurement object without gap

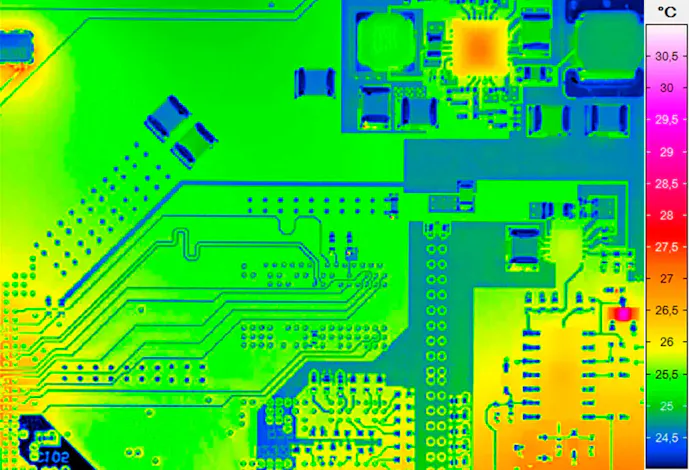

High resolution thermal images for temperature measurement

Precise detection of smallest temperature differences

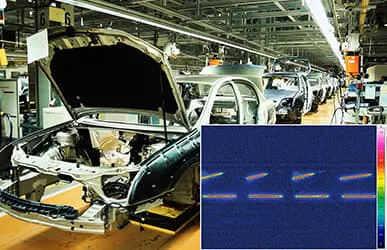

Constant excellent optical and metrological performance even in harsh industrial environments

Camera control and output of control signals for external devices

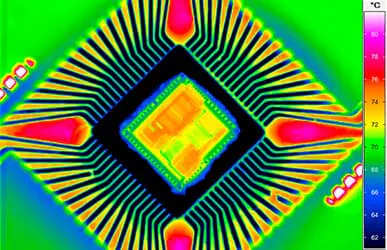

Detection of Minor Defects Through High Thermal Resolution

The thermal resolution describes the process to dissolve slightest temperature differences and thus, can display this measurement value. The infrared cameras of the VarioCAM® HDx head series have a high thermal resolution of better than 0.03 K that helps to display even slightest temperature differences with accuracy. In combination with the high-performance lenses this helps to detect critical faults at an early stage and display these in excellent quality.

Unrestricted Operation of the Infrared Camera in Harsh Industrial Environments

The robust light metal housing (protection degree IP67*) is ergonomically flexible designed according to the users needs. It provides reliable protection for the high sensitive optronics of the device. In addition, it guarantees trouble-free operation even in harsh industrial environments and keeps constant the excellent optical and metrological performance parameters of the device over a long service life. The high-resolution, light intensive colour display of the infrared camera is integrated in the light metal housing. In this way a long-term and trouble-free operation of the VarioCAM® HD head is guaranteed. The usage of a high-quality LEMO connector technology ensures a high protection degree of the infrared camera even for computer-based network operations.

Autofocus for Optimal Focusing

Constantly changing object scenes require manual or automatic refocusing activated by the user. The optional permanent autofocus function facilitates this work. In case there is a scene change the camera automatically adopts fast and precise the optimal focusing.

Technical Specifications

| Spectral range | (7.5 … 14) µm |

| Detector | Uncooled Microbolometer Focal Plane Array |

| Detector format (IR pixels) | (640 × 480) |

| Temperature measuring range | (-40 … 600) °C, up to 1,700 °C* |

| Measurement accuracy | ± 2 °C or ± 2 % |

| Temperature resolution at 30 °C | Up to 0.03 K* |

| Frame rate (full / half / quarter / sub frame) | Full-frame: 30 Hz (640 × 480), sub-frame: 60 Hz (384 × 288) |

| Window mode | Yes |

* Depending on model

** In selected measurement ranges

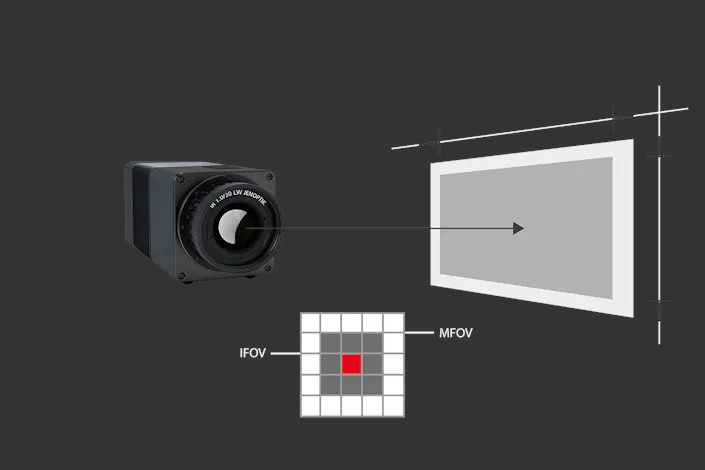

Configure Your Camera System

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Benefit from a Specialized Software

Temperature differences in defective and intact structures often account for only a few milli- and microkelvin. Thermography software IRBIS® 3 active is a sufficient tool for such ambitious material testing. It supports Lock-in Thermography with active electrical excitation of corresponding testing objects for the detection of defects and provides crucial benefit to your research and development:

Analysis with different active thermography methods

Superimposition of different views at the pixel level to pinpoint abnormalities at their location successfully and precisely

High-frequency excitation during measurements to gain more detailed information

Easily save, neatly organize and quickly retrieve various parameter settings

Further information about thermography software IRBIS® 3 active

Do You Want to Know More About the InfraTec Service?

Our experienced service team will be happy to assist you.

Product Flyer

Get all the information you need at a glance in our product flyers