Thermographic Microscopy in Electronics

At the same time that the performance of electronic components is being driven ever higher the demand for thermal management at ever smaller scales is also occurring.

At the same time that the performance of electronic components is being driven ever higher the demand for thermal management at ever smaller scales is also occurring. The Fraunhofer Institute for Silicon Technology (ISIT), as a development partner, supports companies in meeting these growing needs in an optimal fashion. As a result, the latest scientific developments can be implemented in new products very quickly, sus-taining the rapid rate of innovation required by the industry. In order to deal with this challenge, the ISIT, as well as other Fraunhofer Institutes, has a range of excellent technology. This technology enables its specialists to fulfill their tasks in the very best way.

InfraTec Solution

Fraunhofer Institute for Silicon Technology (ISIT)

25524 Itzehoe

www.isit.fraunhofer.de

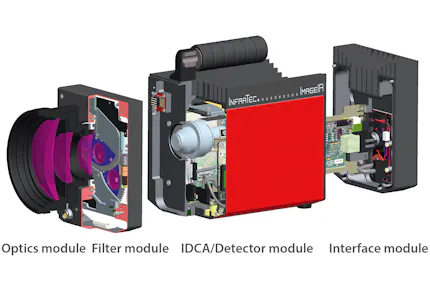

Infrared camera

ImageIR® 8300

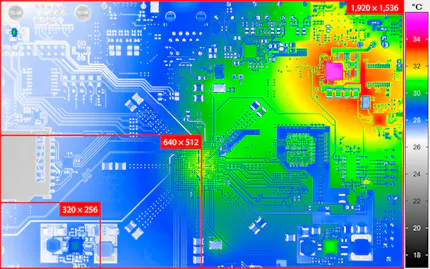

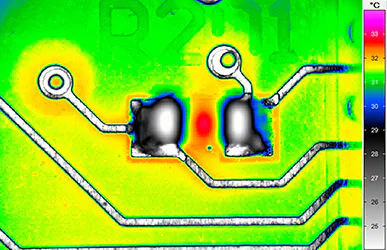

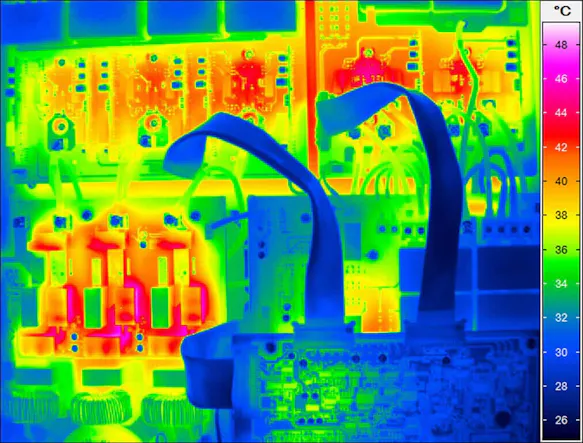

Analysing electronic components the ISIT has to detect smallest possible temperature differences. It does so by using the thermal camera ImageIR® 8300 from InfraTec which can precisely measure temperature differences of 20 mK securely identifying any even just emerging thermal issue. Thus, development failures can be avoided at an early stage. By using a detec-tor with (640 x 512) IR pixels at a 15 µm pitch and a high performance 3x microscopic lens a geometric reso-lution of only 5 µm can be achieved. At the same time, a field of view of (3.2 x 2.6) mm2 is displayed which is suitable for many microelectronic applications. Additional, easily interchangeable lenses with a range of focal lengths enable the ISIT to further exploit the flexibility of their infrared camera across a wide variety of applications.

Another benefit for the ISIT derives from the precision calibration of the ImageIR® 8300 camera. The use of a set of additional side calibration curves compensates for drift and ensures a maximum measurement accuracy even under fluctuating measurement conditions. As with all thermographic testings of electronic components and circuits, measurements are influenced by the differing emissivity of the individual components. To overcome this situation, InfraTec offers an automated pixel wise emissivity correction routine directly in its control and analysis software IRBIS® 3. Using these tools precise statements can be made about temperature distributions and developments over time. With the time component of the heating playing an increasingly important role in the ever decreasing sizes of components, the ISIT is able to take advantage of the multi-kHz frame rates possible with the ImageIR® 8300.