FIRE-SCAN for Li-Ion Batteries

Early Fire Detection in Warehouses and Assembly Halls

Automatic alarm triggering when critical temperature thresholds are exceeded

Segmentation of image areas for alerting

Documentation of alarm situations to analyse potential causes of fire

Localisation of heat sources, even in dusty or smoke polluted environments to prevent thermal runaway

Designed for continuous operation 24 h / 7 without supervision

Camera feed can be routed to control room or other locations

Single or multi-camera systems possible

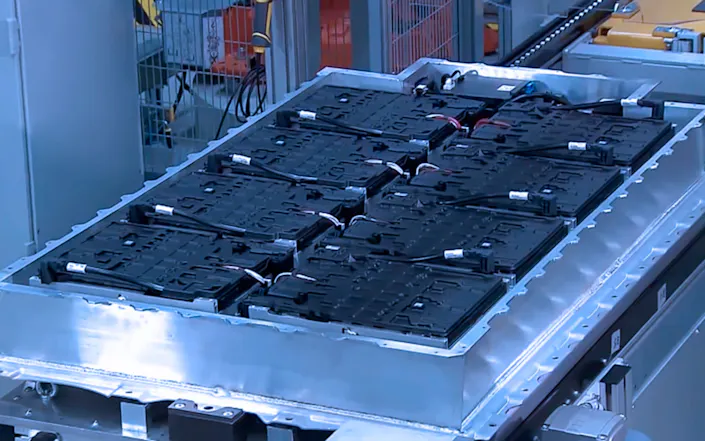

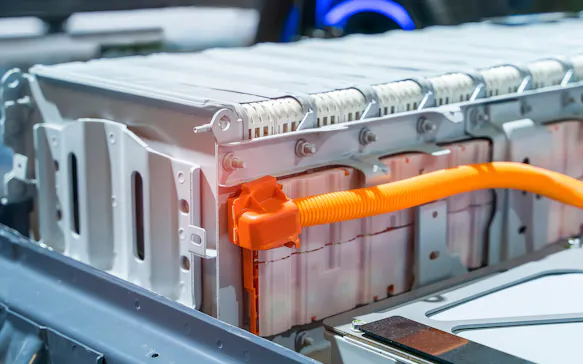

Batteries play a vital role in many areas of modern life. Since the introduction of lithium-ion batteries in the early 1990s, mobile energy supply has become significantly more efficient, and the technology has become widely established. Today, various cell chemistries are available—such as lithium nickel manganese cobalt oxide or lithium iron phosphate—chosen according to requirements for energy density, safety, cycle stability, and battery life.

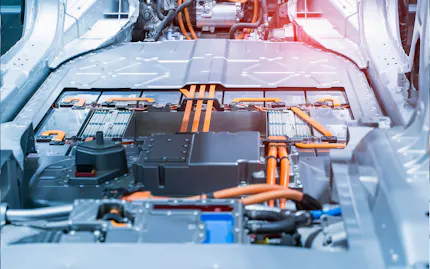

Electromobility and the storage of intermittent energy from wind and solar power are driving a sharp increase in demand for high-performance rechargeable batteries. Manufacturers of electric vehicles, as well as producers of high-voltage batteries for electric cars, buses, e-scooters, e-bikes, and large-scale energy storage systems, are among the main beneficiaries of this trend.

However, the manufacture and storage of energy storage devices involve a few risks. Lithium-ion batteries are prone to thermal runaway and can quickly catch fire if overheated, releasing gases that are highly dangerous to humans. Reliable and accurate temperature measurement using thermal imaging can detect overheating early, allowing affected components to be removed in time.

What is a thermal runaway and why is it so dangerous?

Thermal runaway describes a process that is accelerated by increased temperature, in turn releasing energy that further increases temperature. (Wikipedia)

In batteries, manufacturing defects, incorrect storage or mechanical damage can cause a battery cell to overheat. The heat generated can ‘infect’ neighbouring cells and trigger a chain reaction. Since batteries are usually sealed, overheating and the release of gases lead to an increase in pressure in the cell and ultimately to an explosion. If the irregular heating is detected early, the battery can be prevented from going into runaway mode and causing major damage.

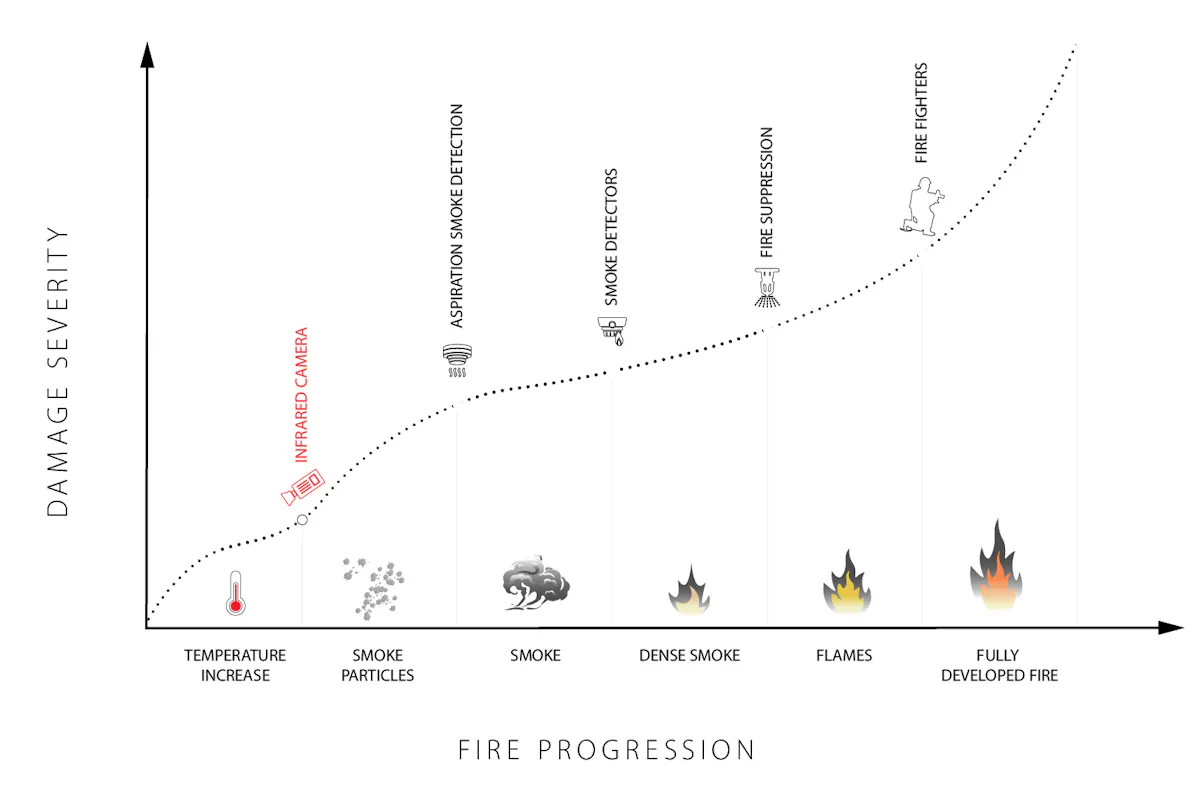

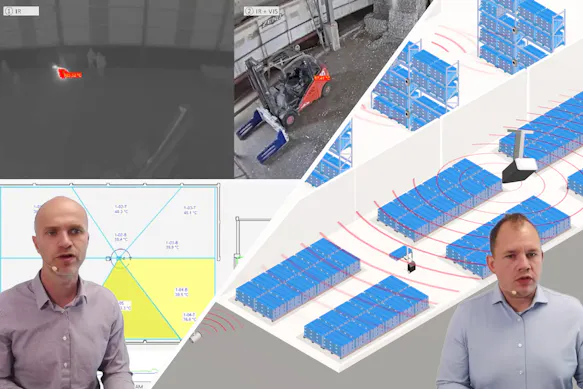

In response to such dangerous scenarios, InfraTec offers the FIRE-SCAN thermography automation solution, which provides a fully automated method for monitoring assembly and storage halls and detecting fire hazards at an early stage. The system, consisting of a high-performance infrared camera and dedicated software, continuously monitors temperature developments at workstations and storage locations around the clock, reliably identifying heat sources before thermal runaway occurs. If critical temperature thresholds are exceeded – even in small areas of the thermal image – FIRE-SCAN triggers an automatic alarm, enabling rapid intervention to prevent a fire.

Advantages of the FIRE-SCAN Thermography System

Large detector with highest geometric and thermal resolution

Analysis of temperature changes and gradients in full frame

Standard interface for easy integration into existing process environments

Camera operation under harsh environmental conditions

Robust metal housing for wide range of environmental conditions and IP rating requirements

Not all batteries are the same – Find the optimal FIRE-SCAN Solution

Many different cell chemistries are used in lithium-ion batteries. The most common are lithium nickel manganese cobalt oxide (Li-NMC) and lithium iron phosphate (LiFePO₄, LFP).

Li-NMC batteries exhibit typical thermal runaway behaviour when defective—meaning a fire can break out within minutes. For NMC batteries, it is therefore essential to detect even small hot spots quickly and reliably. This requires both high geometric resolution and high thermal sensitivity (NETD) in the infrared camera.

LFP batteries, on the other hand, heat up slowly and steadily when defective, sometimes accompanied by outgassing. In these cases, it is crucial to detect dangerous trends, even if the absolute temperature does not initially appear critical.

InfraTec offers the right thermographic cameras for both scenarios. Our application engineers can help you select the optimal solution for your specific measurement task.

Online: Events On Demand: Fire Prevention Solutions

Thermography Systems for Early Fire Protection

Thermographic Warehouse Monitoring for Fire Prevention

Thermography in early fire detection: challenges, important parameters and their influence

FIRE-SCAN for thermographic warehouse monitoring

FIRE-SCAN for monitoring Lithium-ion batteries

High resolution infrared cameras with pan/tilt heads

Special infrared cameras for stationary installation

Thermography for Industrial Automation

Efficient quality control through fast, contactless temperature measurement during ongoing production

Flexible system solutions from modular components to fully customized turnkey setups

Integrated software for automated evaluation, documentation, and triggering of follow-up processes

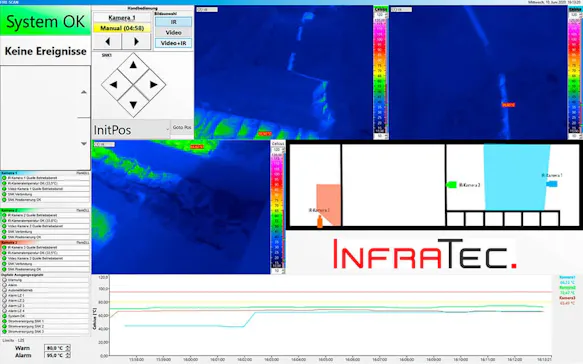

Alarm Release

Automatic alarm release when temperature values exceed critical thresholds

Multi-stage alarming functionality for controlled escalation

Selection of subareas (sectors) within the thermal image

Logging and analysis of long-term temperature trends with adjustable time basis

Documentation of alarm situations to analyse the potential causes of fire

Modular design concept for tailored solutions

Customised System Concept

Designed for continuous operation 24/7 without supervision

Camera feed can be routed to control room or other locations

Flexible wiring technology (copper or fibre optic cable)

Uninterruptible power supply*

System maintenance through integrated PC in the control cabinet (via remote control*)

High-performing Software

Continuous display of the current thermal images of all sectors (mosaic-overview)

Simultaneous display of thermographic and colour video live image*

Camera and system status indication

Merging of live images of thermography and video camera

Recording of maximum, minimum and average temperature of each sector

Single or multi-camera system available

Graphic data display of temperature-time profiles of all sectors

Logging of operations

Filing of image data

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

High-resolution Infrared Cameras

Uncooled FPA-Microbolometer detectors

High geometrical resolution and thermal sensitivity

High-contrast, brilliant thermal images

Localisation of hot spots even in dusty or smoke polluted environments

Spectral range (7.5 … 14) μm

Real-time data acquisition (Gigabit Ethernet)

Internal automatic calibration

Rugged housing according to industrial standard IP65

Pan/tilt systems to extend the detection areas*

Extremely high level of system availability

Digital colour video camera*

*optionally available

Product Flyer

Get all the information you need at a glance in our product flyers