This function is particularly useful for lenses with a shallow depth of field and for non-planar measurement scenarios, where different areas of the test object lie at varying distances from the lens. This is often the case with microscope images.

The multifocus function employs advanced algorithms to merge several thermographic images captured at different focus settings into a single image in which all structures appear sharply defined. The result is a detailed and precise representation of the entire scene—without the need for multiple separate images. This significantly expands the range of applications for the infrared camera and enhances its ease of use.

These are the Benefits for Users Utilizing Multifocus Function

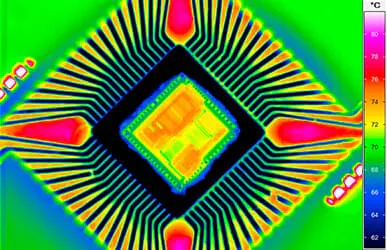

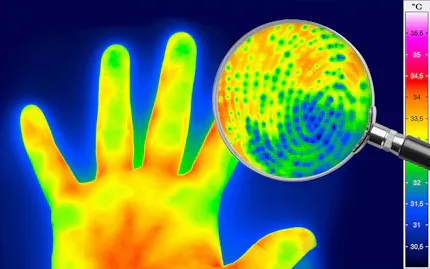

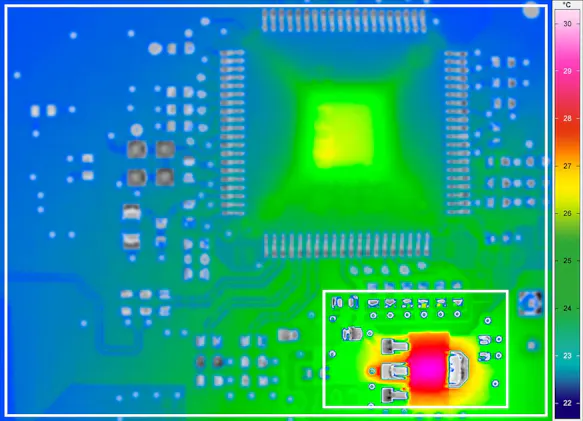

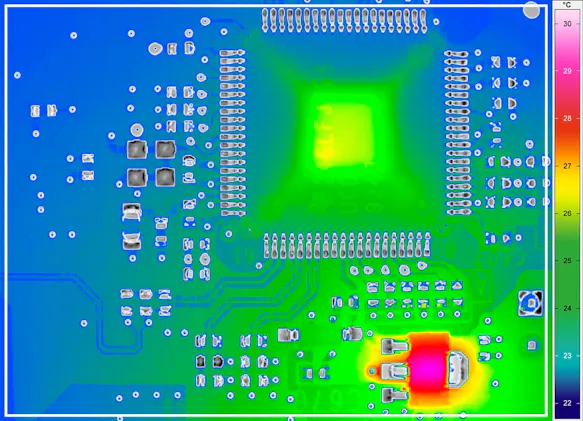

The practical benefits of the multifocus function are particularly evident in microthermographic analyses in electronics. As complex assemblies shrink while gaining in performance, precise troubleshooting becomes increasingly critical. With the VarioCAM® High Definition camera series from InfraTec, structures as small as 17 μm can be analysed. Using the ImageIR series with a microscope lens, even finer details can be examined (see FOV calculator). Thanks to the multifocus function, these structures remain consistently sharp across the entire thermal image, regardless of their distance from the lens, enabling highly accurate temperature measurements. This ensures results of the highest measurement precision for users.

Without Multifocus Function

Part of the thermal image in focus

With Multifocus Function

Highest sharpness of detail of all object structures

Benefits of Multifocus Function at a Glance

Faster analysis of an image scene due to sharply represented details

Compensation of varying object distances

Maximum optical resolution even when using lenses with a short depth of field

Avoidance of measurement errors due to unwanted visual effects (e.g. out of focus blurring)

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.