33 found

Complete Infrared Camera Assortment

Choose the ideal solution for your requirements from over 30 different infrared camera models. Every system solution is suitable for specific use in selected thermographic application areas - such as e. g. industry and research, aerial thermography and the support of monitoring and investigation tasks.

High-End Cameras Meet Highest Demands

Our high-end cameras are designed for particularly demanding applications and, due to their characteristics, are tailored to users who require high-performance and flexibly configurable thermal imaging camera technology. Cooled photon detectors of different types, spectral sensitivity ranges and formats are used.

The high-end cameras of the ImageIR® series offer users outstanding performance data, including the highest thermal sensitivity, first-class geometrical and temporal resolution for precise measurements as well as high-speed modes to optimally image even extremely fast processes and moving objects. Due to a modular basic concept, individual system configuration and optimal adaptation of the performance data to the task are easily possible. For example, our ImageIR® cameras are used in research and development, in non-destructive analysis and in process monitoring.

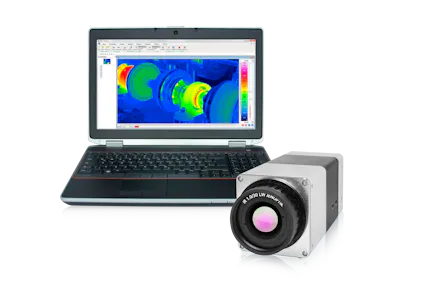

In combination with the thermography control and analysis software IRBIS® developed by InfraTec, the cameras of the ImageIR® series set high standards as an efficient tool for complex thermographic analyses.

System Cameras for Industrial and Laboratory Use

A wide range of interchangeable lenses and the compact housing dimensions of our system cameras as well as the robust construction with a degree of protection up to IP67 make these infrared cameras useful tools for many areas of application in industry and research. They can be easily integrated into existing system environments by using the Software Development Kit (SDK). All system camera series are available in numerous equipment and performance variants and enable - depending on the application focus and requirements - individual thermography solutions.

We offer a variety of flexibly usable system camera models of different performance classes and spectral sensitivity ranges. These include the ImageIR® series cameras measuring in the short-wave infrared range, which are predestined for high-temperature applications. The universally applicable cameras of the VarioCAM® HD head product series, on the other hand, are particularly suitable for demanding measuring and monitoring tasks.

The respective service package includes the control and analysis programme of the IRBIS® software family developed by us. Among other things, it allows the collected temperature measurement data to be analysed and evaluated.

Small, Light, and Robust – Compact Cameras for a Wide Range of Applications

Our compact cameras of the series TarisIR® mini with a detector format of (640 × 480) IR pixels are designed for universal use and enable users to enter stationary thermography at an excellent price-performance ratio. These cameras stand out due to their very compact design, low weight and modern interfaces. Using the supplied software development kit (SDK) and other accessories, flexible integration into existing – even harsh – system environments is easily possible.

These infrared cameras are the smallest cameras in InfraTec's portfolio. This makes them ideally suited for use as OEM modules in machines as well as in systems for process monitoring. Combined with the IRBIS® software developed by InfraTec, they can also be used as PC-supported camera systems in the measurement setup of a laboratory. Our compact cameras are suitable for a wide range of measuring, testing and monitoring tasks in almost all areas of industry and science, such as the plastics industry, additive manufacturing or electronics.

Zoom Cameras – Convenient and Long Ranges

Our radiometric infrared zoom cameras allow universal and efficient use with very different or rapidly changing image fields without time-consuming lens changes and the need to interrupt the measurement. They can be used to capture large objects completely from a short distance as well as the smallest objects from a long distance and to measure their temperatures precisely. Their outstanding technical features make them suitable for a wide range of measuring and monitoring tasks.

InfraTec's powerful and intuitive to operate IRBIS® thermography software complements the infrared cameras with a wide range of camera control and editing tools designed to meet different user requirements. It allows detailed analyses in an efficient way.

OEM Camera Modules for Customised System Integration

Due to their modular basic concept, our OEM cameras can be configured with such flexibility that they can be easily integrated into existing system environments as an individually adapted solution. Integrators benefit from numerous advantages, such as the availability of different performance classes of detectors as well as optical and electronic components. Furthermore, the OEM modules offer variable interfaces to automation and image processing PCs that are compatible with industrial standards such as 10 GigE, GeniCam, GigE Vision and CAMLink. Easy and quick integration into existing systems is possible using the supplied Software Development Kit (SDK).

Further details about OEM camera modules

The OEM modules of our ImageIR® camera series provide the perfect solution for very challenging applications that require the highest performance in terms of thermal sensitivity, accuracy, spatial resolution, and image speed.

We also offer OEM modules with uncooled detectors based on the VarioCAM® HD camera series. Configured specifically for the application, these OEM cameras are suitable for integration into small installation spaces and for tasks that require cost-optimised 24/7 operation.

Configure Your Camera System

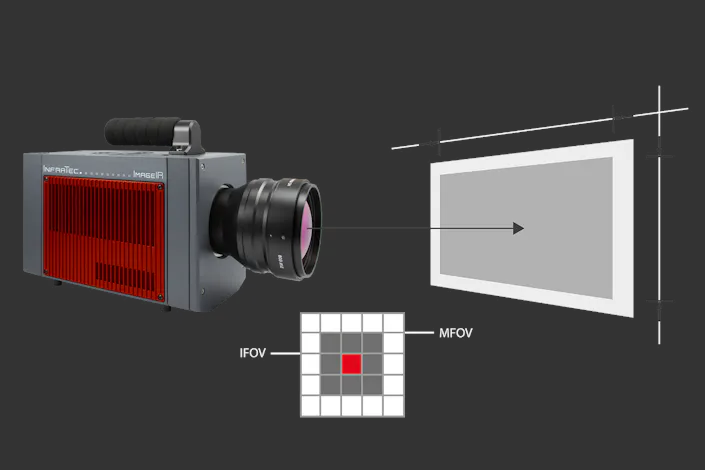

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Infrared Camera as a Useful Precision Thermography Device

Temperatures are Captured with an Infrared Camera

An infrared camera – also called IR camera, thermal imaging camera or thermal camera – is a measurement device, which can capture temperature distributions on object surfaces without touching the object. In order to achieve this, the infarerd radiation of objects or bodies, which is invisible to the human eye, is made visible. We – InfraTec GmbH – offer a wide range of thermographic measurement devices for this purpose.

What can Infrared Cameras be Used for?

The benefit of non-contact temperature measurement technology is the capability to inspect objects non-destructively and contact-free and to make material conditions in deeper layers visible. The contact-free measurement of temperature distributions on objects or in processes constantly informs about the state of the object. Thus, deviations of the production standard can be recognised. InfraTec specialised on developing reliable high-class infrared camera models for all application fields of thermal imaging.

More Than 30 InfraTec Infrared Cameras for Various Application Fields

Choose the ideal solution for your requirements from our numerous different infrared camera models. Every system solution is suitable for specific use in selected thermographic application areas, ranging from preventive maintenance, process optimisation, quality assurance and assembly optimisation to active thermography.

Our infrared cameras of the high-end series are designed for particularly demanding applications in the field of research and development, for non-destructive testing as well as process monitoring. These infrared cameras are based on a modular design concept enabling excellent adjustment to the respective applications.

Our compact cameras are the smallest infrared cameras in our portfolio. Designed for universal use, they enable users to enter stationary thermography at an excellent price-performance ratio. Compact dimensions, low weight and the equipment with modern interfaces as well as the supplied Software Development Kit (SDK) facilitate integration into existing system environments.

Our system cameras from InfraTec have a wide range of interchangeable lenses and, in addition to compact housing dimensions, have a robust construction with a degree of protection up to IP67. All infrared cameras of this series are available in numerous equipment and performance variants and enable customised thermography solutions.

With our radiometric infrared zoom cameras you can detect smallest objects and measure their temperatures even over long distances. With their various technical features, they are suitable for measurement tasks in research & development or quality assurance as well as in the field of security applications, e. g. for surveillance tasks.

Thermography Software and Training Seminars by InfraTec

Extensive equipment, informative manuals and suitable thermography software is available for every infrared camera model. The extensive, modular thermography software family IRBIS® 3 is the ideal tool for analysis of thermographic measurement data and for comfortable generation of Word reports. IRBIS® 3 is compatible with all infrared cameras in the InfraTec assortment.

InfraTec will still be your best partner after you purchase your infrared camera. In InfraTec’s seminars, you will be able to learn everything you need to know about infrared thermography in theory and also in practical experiences. For advanced users, InfraTec offers the certified thermography course level 1 (in accord with DIN 54162 and EN 473).