33 found

Configure Your Camera System

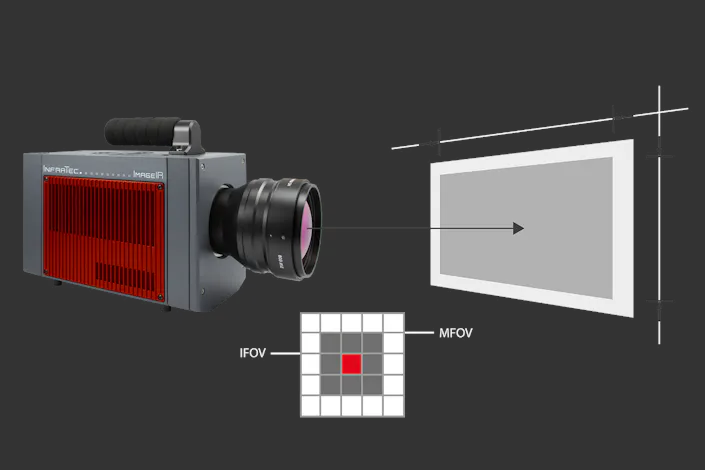

Each measurement or testing task has its own characteristic basic conditions. For getting optimal results camera, detector and lens have to be perfectly matched to one another. The field of view calculator helps you to determine the appropriate combination.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Questions and Answers about Thermal Imaging Cameras

Yes. The high-end infrared cameras of the ImageIR® series are developed and manufactured at InfraTec's headquarters in Dresden. In production, approximately 20 employees configure the modular cameras according to requirements and the specific measurement and testing situation. The selection of the appropriate precision infrared lenses is also carried out at InfraTec. The cameras are calibrated on site using a fully automatic calibration machine.

The high-end infrared cameras of the ImageIR® series are developed and built at the company's headquarters in Dresden. A team of experienced scientists, engineers, and technicians are constantly working to improve the products and open up new areas of application for InfraTec cameras.

The ImageIR® infrared cameras are unique: each of the modular devices is manufactured in a modern production facility according to customer requirements and calibrated on a fully automated calibration stand.

Within Europe, there are no customs or trade restrictions on InfraTec infrared cameras or on the products used by suppliers in their production concerning InfraTecs infrared cameras. Our strategic purchasing and professional supplier management ensure the availability of our infrared cameras at competitive prices.

None of the cameras sold by InfraTec are subject to the International Traffic in Arms Regulations, the US government's regulations for controlling the export and import of defense goods and services. The classification as ITAR-free allows worldwide export, for example to the USA or China.

InfraTec products are used worldwide. The delivery of infrared cameras is organized from the headquarters in Dresden, where experienced employees take care of all formalities such as the preparation of waybills, packing lists, customs declarations, etc., and ensure compliance with import and export regulations. InfraTec relies on established logistics service providers for the transport and delivery of infrared cameras.

Infrared cameras are high-quality, technically complex products. InfraTec supports its customers far beyond the purchase of a thermography system. The in-house service department staff assist users with questions or technical challenges, for example, via remote maintenance. They also recalibrate infrared cameras as needed.

InfraTec offers a comprehensive range of accessories. In the event of a defect, replacement parts can be provided at short notice. In addition, the accessories offer the opportunity to flexibly adapt testing and measurement systems to new and changing tasks.

Complete Infrared Camera Assortment

Choose the ideal solution for your requirements from over 30 different infrared camera models. Every system solution is suitable for specific use in selected thermographic application areas - such as e. g. industry and research, aerial thermography and the support of monitoring and investigation tasks.

Infrared Camera as a Useful Precision Thermography Device

Temperatures are Captured with an Infrared Camera

An infrared camera – also called IR camera, thermal imaging camera or thermal camera – is a measurement device, which can capture temperature distributions on object surfaces without touching the object. In order to achieve this, the infarerd radiation of objects or bodies, which is invisible to the human eye, is made visible. We – InfraTec GmbH – offer a wide range of thermographic measurement devices for this purpose.

What can Infrared Cameras be Used for?

The benefit of non-contact temperature measurement technology is the capability to inspect objects non-destructively and contact-free and to make material conditions in deeper layers visible. The contact-free measurement of temperature distributions on objects or in processes constantly informs about the state of the object. Thus, deviations of the production standard can be recognised. InfraTec specialised on developing reliable high-class infrared camera models for all application fields of thermal imaging.

More Than 30 InfraTec Infrared Cameras for Various Application Fields

Choose the ideal solution for your requirements from our numerous different infrared camera models. Every system solution is suitable for specific use in selected thermographic application areas, ranging from preventive maintenance, process optimisation, quality assurance and assembly optimisation to active thermography.

Our infrared cameras of the high-end series are designed for particularly demanding applications in the field of research and development, for non-destructive testing as well as process monitoring. These infrared cameras are based on a modular design concept enabling excellent adjustment to the respective applications.

Our compact cameras are the smallest infrared cameras in our portfolio. Designed for universal use, they enable users to enter stationary thermography at an excellent price-performance ratio. Compact dimensions, low weight and the equipment with modern interfaces as well as the supplied Software Development Kit (SDK) facilitate integration into existing system environments.

Our system cameras from InfraTec have a wide range of interchangeable lenses and, in addition to compact housing dimensions, have a robust construction with a degree of protection up to IP67. All infrared cameras of this series are available in numerous equipment and performance variants and enable customised thermography solutions.

With our radiometric infrared zoom cameras you can detect smallest objects and measure their temperatures even over long distances. With their various technical features, they are suitable for measurement tasks in research & development or quality assurance as well as in the field of security applications, e. g. for surveillance tasks.

Thermography Software and Training Seminars by InfraTec

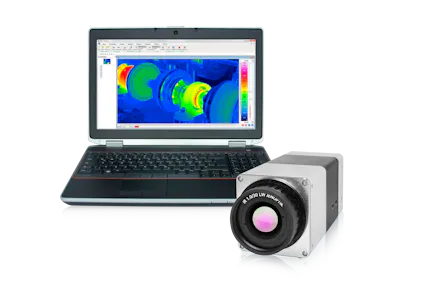

Extensive equipment, informative manuals and suitable thermography software is available for every infrared camera model. The extensive, modular thermography software family IRBIS® 3 is the ideal tool for analysis of thermographic measurement data and for comfortable generation of Word reports. IRBIS® 3 is compatible with all infrared cameras in the InfraTec assortment.

InfraTec will still be your best partner after you purchase your infrared camera. In InfraTec’s seminars, you will be able to learn everything you need to know about infrared thermography in theory and also in practical experiences. For advanced users, InfraTec offers the certified thermography course level 1 (in accord with DIN 54162 and EN 473).