Industrial Automation

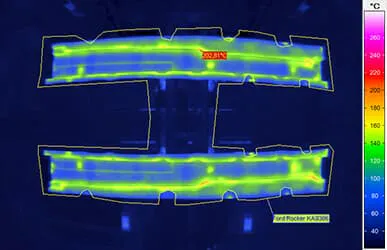

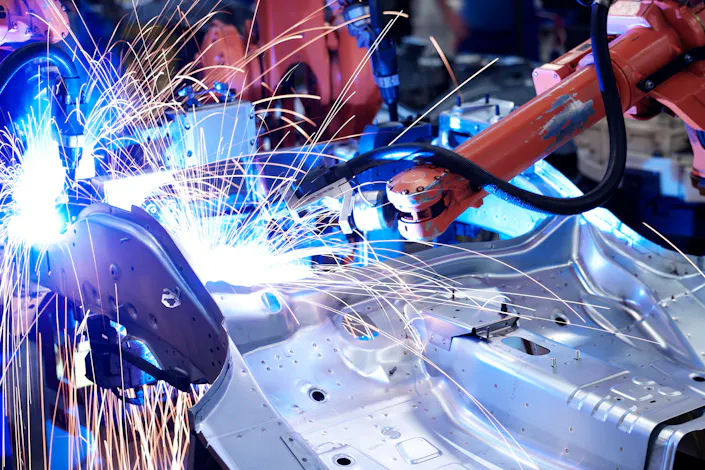

The contactless measurement of temperature distributions with thermographic cameras allows efficient and reliable monitoring and control of temperature-critical processes or automatic quality control in the industry. During the technical implementation of tailored automation solutions you benefit from our flexible modules of industrially tested components. This includes thermal imaging cameras of different performance classes, protective casings as well as pan/tilt heads. The digital data of the thermographic camera is distributed via modern data transmission systems. It makes no difference whether you want to document temperature profiles with analysable data or whether you want to control processes directly.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Industrial Automation: Benefits of Using Thermography

The infrared testing systems are designed for fixed mount and handheld use.

You obtain production-integrated, flexible solutions.

Semi or fully automatic operation ensures a high throughput of components.

The complete final inspection of the components is possible.

In future you will reliably detect even the smallest defects.

A compensation method developed by InfraTec reduces the environmental interference radiation on reflecting surfaces.

With the powerful analysis software you can create evaluation models according to different algorithms.