Fire Protection in Wood Pellet Storage

Wood pellets as an alternative and high-quality fuel have become increasingly important in recent years. Their local origin from sustainable cultivation in the region has given WUN Bioenergie GmbH the opportunity to respond to market demand as an environmentally friendly supplier of raw materials. However, like other fuels, stored wood pellets need to be secured and monitored around the clock to prevent causes of devastating damage in the event of a fire, for example. Robust and reliable thermography solutions are a suitable tool for plant protection here.

At its Wunsiedel site, WUN Bioenergie GmbH has more than one string to its bow. Among other things, it operates a biomass cogeneration plant there. Treetop wood with a high proportion of conifer needles and twig residues are used as heating fuel, as these are cheap and environmentally friendly to procure. The water content amounts to about 30 – 60 percent, which does not pose any problems for the operation of a highly efficient ORC (Organic Rankine Cycle) plant.

InfraTec Solution

WUN Bioenergie GmbH, Wunsiedel, Germany

Wood Pellet Storage

www.s-w-w.com

Thermography Automation System

FIRE-SCAN Fire Prevention

The Production of Regrown Heating Fuel

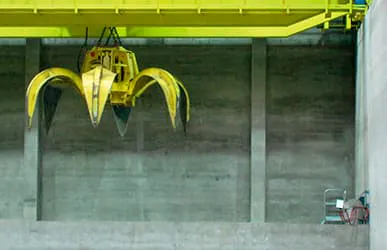

In addition to the CHP (combined heat and power) plant, there is a pellet production facility on site. Annually supplied with about 16,000 truckloads of wood chips and residues, it produces a total of 180,000 tons of pellets. This amount of pellets can be used to provide about 36,000 households with heat. One part of the produced pellets is packed on site and delivered to end customers. The other part is used to supply satellite power plants, which ensures local heating and electricity supply. When the pellets leave the production facility, they have a temperature of more than 100 °C and are transported to a 4,180 m² storage building for cooling, which is designed as an area storage facility to ensure better cooling and fast outgassing after the production is completed.

Fire Protection with FIRE-SCAN

Wood pellets are a high-quality and energy-rich fuel. For this reason, the storage facilities must be monitored around the clock in the interest of fire protection. This is made possible by high-quality thermographic systems that simultaneously track the moisture content of the pellets during the drying process with high thermographic and geometric resolution. The real-time evaluation of the thermal images allows an accurate assessment of this process.

The FIRE-SCAN fire monitoring system from InfraTec is used in the WUN Bioenergie warehouse. This thermography automation solution is equipped with VarioCAM® HDx head infrared cameras and designed for a 24/7 continuous operation. The very stable and highly accurate digital infrared cameras of the VarioCAM® HDx head series from InfraTec are based on thermally and geometrically high-resolution microbolometer FPA detectors with (640 × 480) IR pixels and provide brilliant 16-bit thermal images in real time.

In addition to automated continuous monitoring, the associated software also allows manual interactions by the operating personnel. The surface temperatures measured by the cameras ensure constant quality monitoring of the pellets, as the FIRE-SCAN software monitors another threshold temperature in addition to the threshold values for early fire detection. This allows conclusions to be drawn about the moisture content of the pellets. Thus, the crane operator can actively ensure that the drying process runs smoothly. If the system detects a heat nest at up to 40 °C, the pellets are rearranged by the crane system. At 60 °C, they are removed from storage and, in the event of a fire, extinguished with quartz sand if necessary.

Plant manager Thomas Ködel also states: "Due to the permanent automated observation of the surface, possible hotspots are kept in view even before ignition. In the event of a fire, this enables the extinguishing agents to be controlled with pinpoint accuracy." Furthermore, it eliminates the need to install a sprinkler system that, if triggered incorrectly, would cause damage to the product and, due to the swelling of the pellets, also to the building.

In addition to automated continuous monitoring, the associated software also allows manual interactions by the operating personnel. The surface temperatures measured by the cameras ensure constant quality monitoring of the pellets, as the FIRE-SCAN software monitors another threshold temperature in addition to the threshold values for early fire detection. This allows conclusions to be drawn about the moisture content of the pellets. Thus, the crane operator can actively ensure that the drying process runs smoothly. If the system detects a heat nest at up to 40 °C, the pellets are rearranged by the crane system. At 60 °C, they are removed from storage and, in the event of a fire, extinguished with quartz sand if necessary.

Plant manager Thomas Ködel also states: "Due to the permanent automated observation of the surface, possible hotspots are kept in view even before ignition. In the event of a fire, this enables the extinguishing agents to be controlled with pinpoint accuracy." Furthermore, it eliminates the need to install a sprinkler system that, if triggered incorrectly, would cause damage to the product and, due to the swelling of the pellets, also to the building.