Research and Development in Sensor Technologies

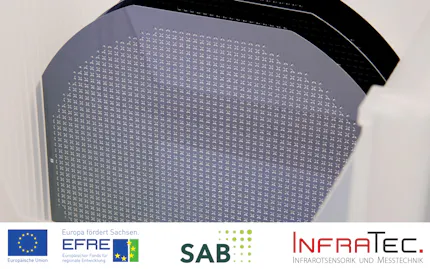

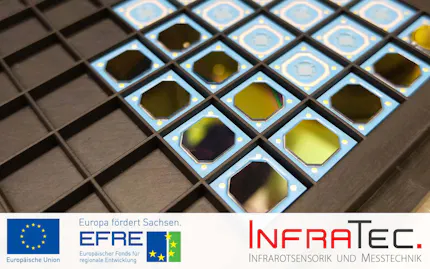

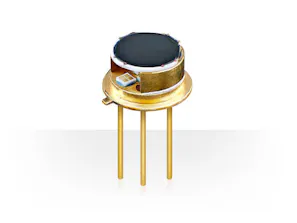

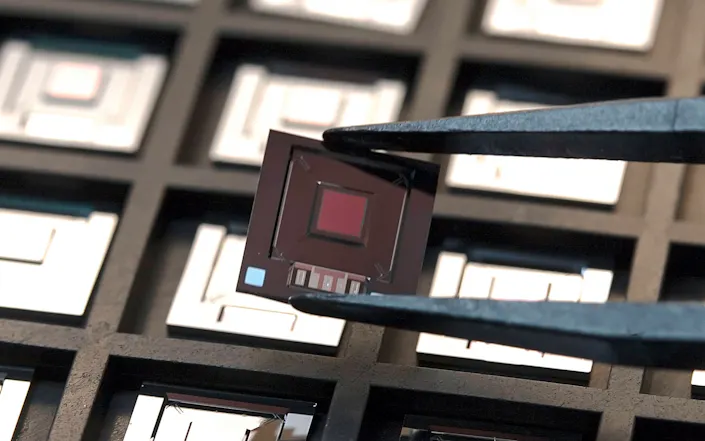

Permanent research and development of new sensor technologies are indispensable in order to meet the customer’s expectations as well as our own detector production requirements. Our developers are very experienced in the fields of electro-optical and electro-mechanical design, pyroelectric materials and signal processing electronics. This knowledge is the basis for developing innovative products as well as for the optimisation of applied production technologies and further development of our extensive measurement techniques.

We permanently increase our development’s workforce as the market is growing, in order to prepare for future request and to be able to react to newest trends, such as the application of microsystem technologies (MOEMS). In addition to product developments for our customers, we also cooperate with different project partners and work on various promotion projects for future infrared sensor generation.

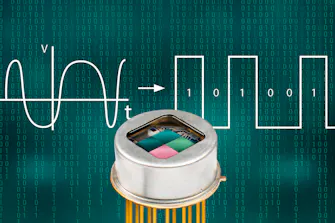

Our know-how is reflected in our products, such as the digital detector (PyrIQ) for easy system integration, which is currently one of the competition-leading innovations.

Would You Like to Know More?

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our experienced engineers, receive further technical information or learn more about our additional services.