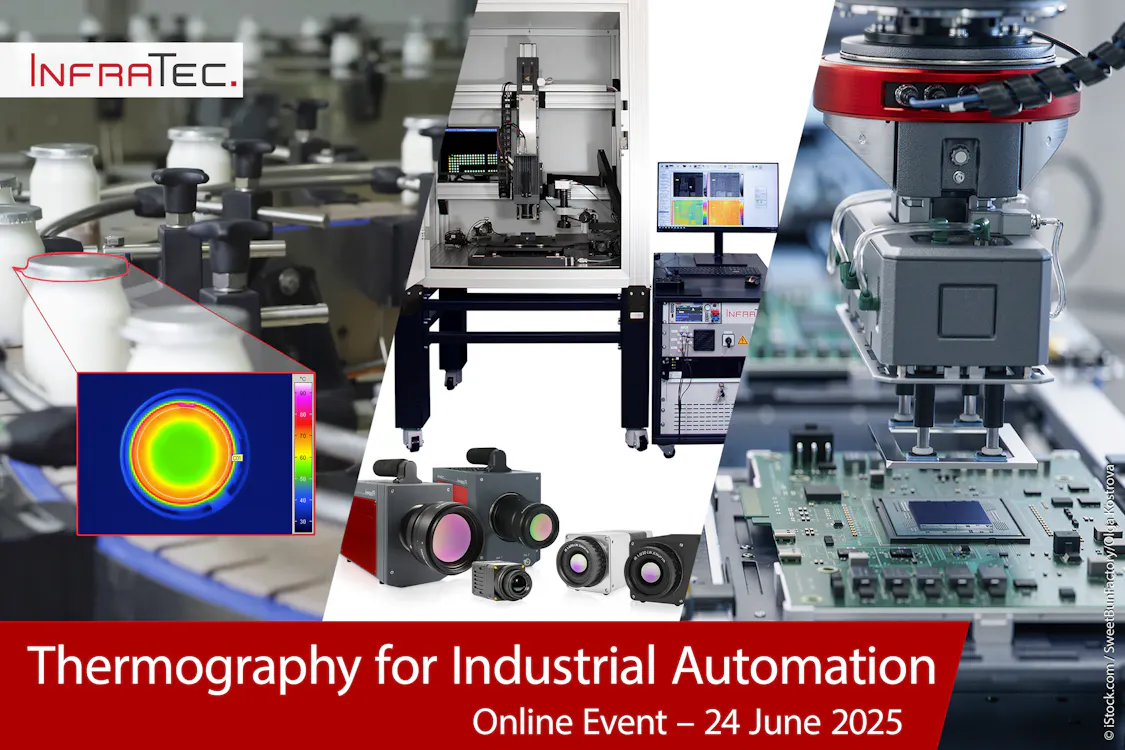

Online Event “Thermography for Industrial Automation”

When optimizing production processes, the recording of temperature and its progression over time often plays a crucial role. Conventional contact-based methods can rarely measure temperature deviations quickly and accurately enough without delaying the production process. As an imaging temperature measurement method that can be tailored to a wide range of measurement tasks, thermography has become an indispensable tool for quality assurance in series production. The method offers a number of benefits for use in industrial automation:

Fast, contactless and completely non-intrusive control during the ongoing process

Flexible adaptation to measurement tasks and specific needs

Evaluation and documentation using integrated software

Automatic triggering of follow-up processes

Versatile application options from cost-effective to highly precise

Find out in our online event how you can harness the enormous potential of infrared cameras in automated quality assurance and monitoring.

Topics at a Glance:

Thermography in industrial automation: potential and challenges.

What is infrared radiation and how do infrared cameras work?

Software interface – results and insights from thermographic evaluations.

Which InfraTec automated thermography solution is right for you?

Online Event “Thermography for Industrial Automation”

Date: Tuesday, 24 June 2025

Time: 10:00 AM – 12:00 PM (CEST)