Case Study: Thermography in CFRP Processing

In 1960 when the first laser was announced there was no indication of how the field would develop and today there is almost no area of science and industry that remains untouched by lasers. New applications emerge almost daily demanding the development of even more sophisticated laser systems and one of the leading global research and development institutions for laser-based solutions and their implementation is Laser Zentrum Hannover e.V. (LZH). Many of these new systems operate at very high laser intensity levels and consequently require close control of thermal processes. This is achieved by the use of infrared thermography which is both contact-less and provides imagery.

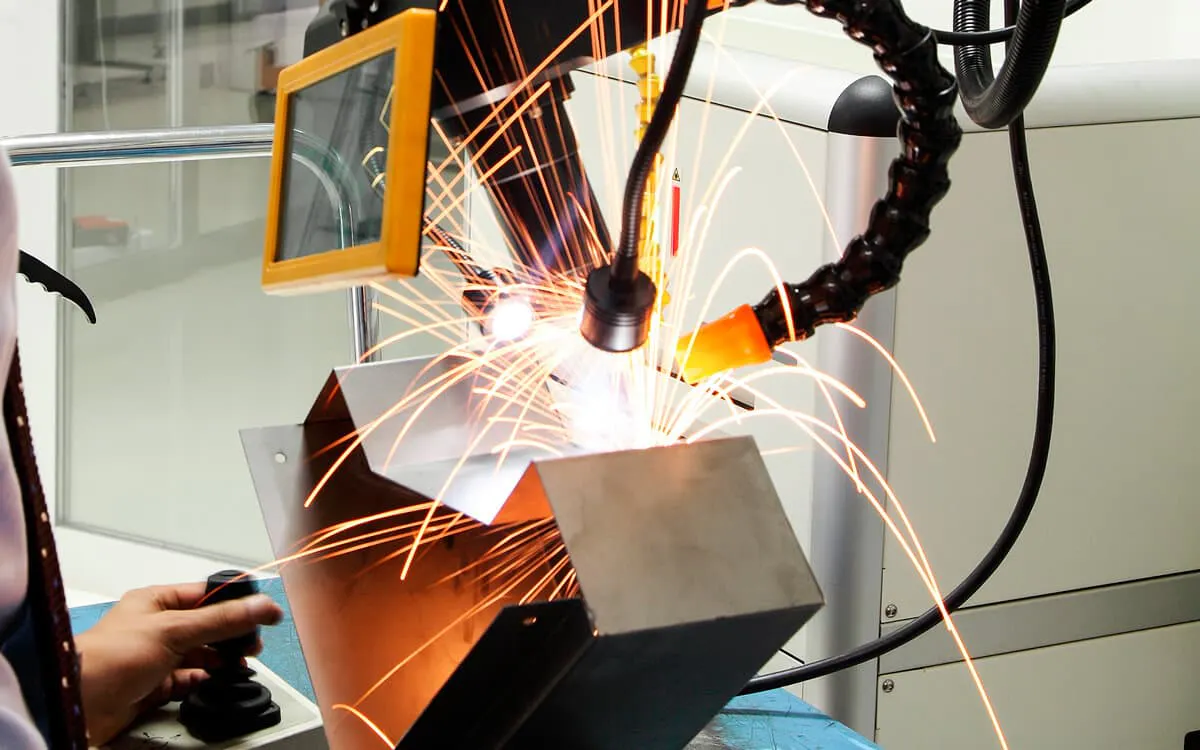

The cutting and welding of carbon fiber reinforced polymer composite (CFPR) requires a precisely defined energy input from the laser. Precision is vital as the carbon fibres only start to melt above 3,000 °C whereas the polymer matrix making up the composite has already begun to melt and vaporize at temperatures as low as 130 °C. Because of the wide variation in the thermo-physical properties of the fibre and matrix a highly precise and temporally resolved temperature measurement is required. Fast image acquisition is necessary as the operational cycles of the laser processes are often very short. Only by using such fast measurement capability can processes be understood overcoming thermal interference effects from the base material in the quality of cut edges and weld seams produced.