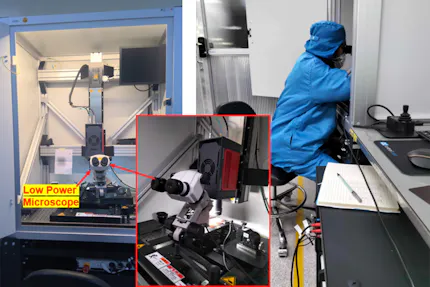

![Fig. 1: Workstation for fault analysis at STM Case study: Workstation for fault analysis at STM]() 2026-02-19Thermographic Fault Isolation on Chips and Power ModulesSTMicroelectronics implements InfraTec's E-LIT solution for analyzing semiconductor componentsRead onDownload ZIP-File (8633 kB)

2026-02-19Thermographic Fault Isolation on Chips and Power ModulesSTMicroelectronics implements InfraTec's E-LIT solution for analyzing semiconductor componentsRead onDownload ZIP-File (8633 kB)Lock-in Thermography is a key method at STMicroelectronics for identifying faults in electrical components. The user-friendly method is especially effective in exactly locating short circuits and other anomalies. Users particularly appreciate the simple visual identification of faults and the flexibility of the system for measurements on different components such as ICs, sensors, LEDs or power modules.

- 2026-02-17Online Event: Detector Talks 2026 – Your Questions About Infrared DetectorsExperts answer users' questions about InfraTec detectors liveRead onDownload ZIP-File (3412 kB)

The free of charge online event “Detector Talks 2026 – Your Questions About Infrared Detectors” offers interested parties the opportunity to benefit from the expertise of InfraTec specialists: practical, well-founded, and in direct exchange. Date: April 28, 2026

- 2026-02-10ImageIR® series: High-performance Infrared Cameras for ProfessionalsA new video showcases InfraTec’s versatile, high-end thermography camerasRead onDownload ZIP-File (11551 kB)

The infrared cameras of InfraTec‘s high-quality ImageIR® series are deployed worldwide in industry and research. Whether the goal is making processes more efficient, ensuring product quality, testing materials non-destructively, or gaining deep insights into physical processes, these high-end infrared cameras made in Germany can be adapted optimally to almost any measurement task. But what is the secret behind this versatility? A new video answers this question, revealing how ImageIR® cameras are made and what sets them apart.

- 2026-02-05Online Event: High-Resolution Aerial ThermographyThermal measurement and inspection using drones, helicopters, or planesRead onDownload ZIP-File (9887 kB)

Our free of charge InfraTec online event "High-Resolution Aerial Thermography" offers you insights in airborne thermography and its possible applications.

- 2026-02-04Online Event: Detector Talks 2026 – Your Questions About Infrared DetectorsExperts answer users' questions about InfraTec detectors liveRead onDownload ZIP-File (3422 kB)

The free of charge online event “Detector Talks 2026 – Your Questions About Infrared Detectors” offers interested parties the opportunity to benefit from the expertise of InfraTec specialists: practical, well-founded, and in direct exchange.