Choose from More Than 30 Models

Statements of our Customers

Would You Like to Know More?

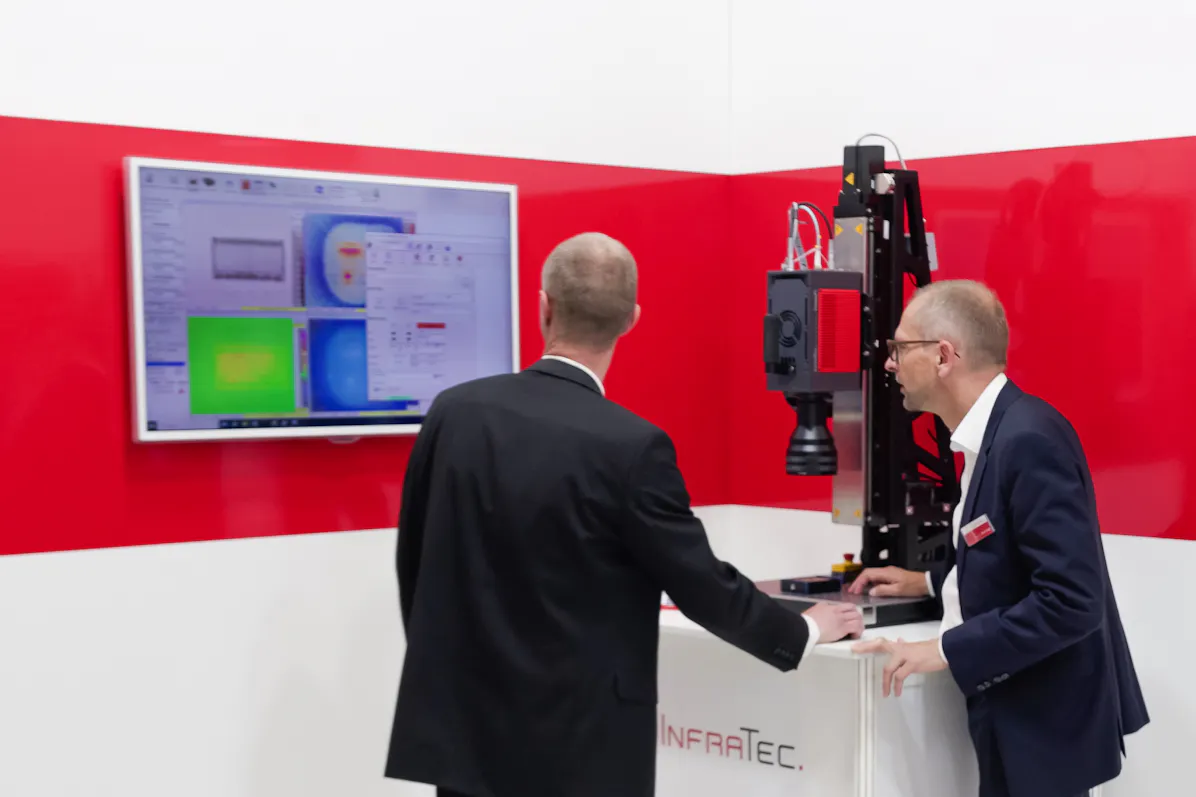

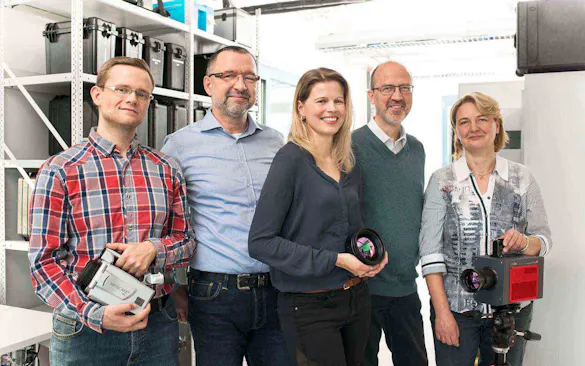

It is not unusual for tasks to be associated with special requirements. Discuss your specific application needs with our specialists, receive further technical information or learn more about our additional services.

Learn More About the Use of a Thermal Camera for Thermal Imaging

Thermal Imaging is a Contactless Measurement Technology

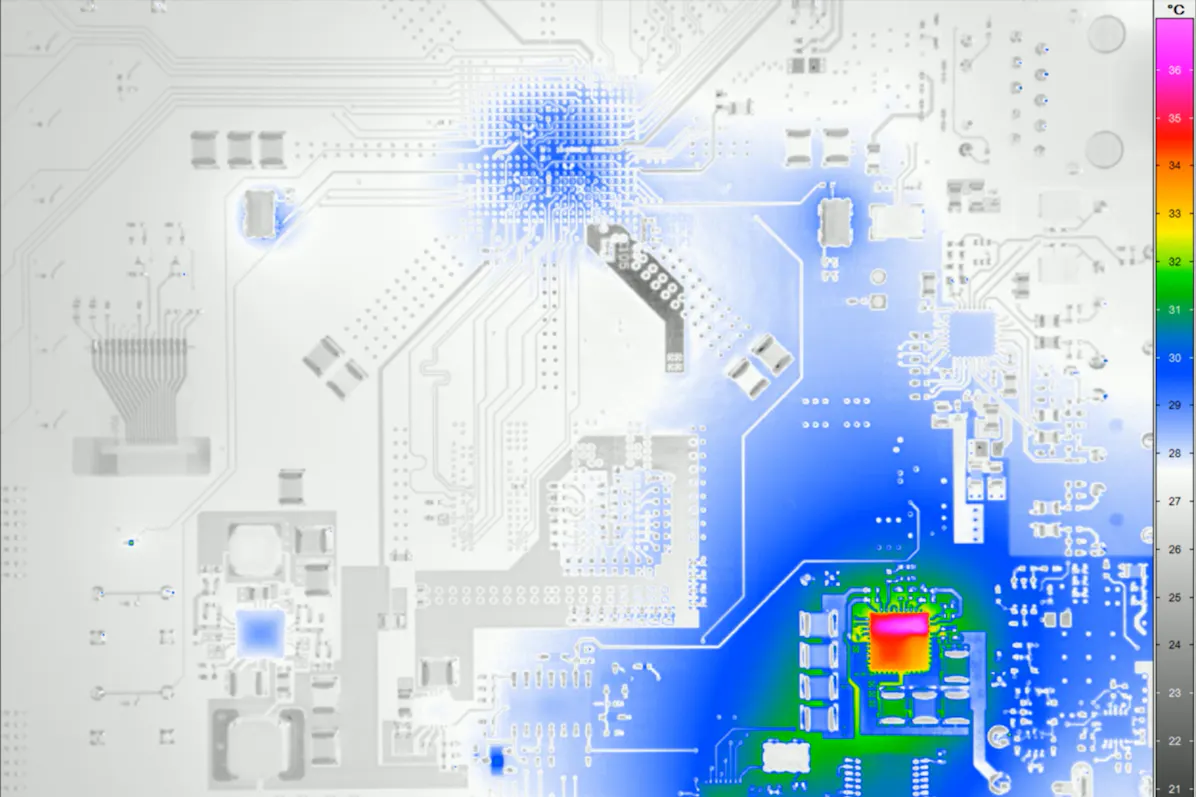

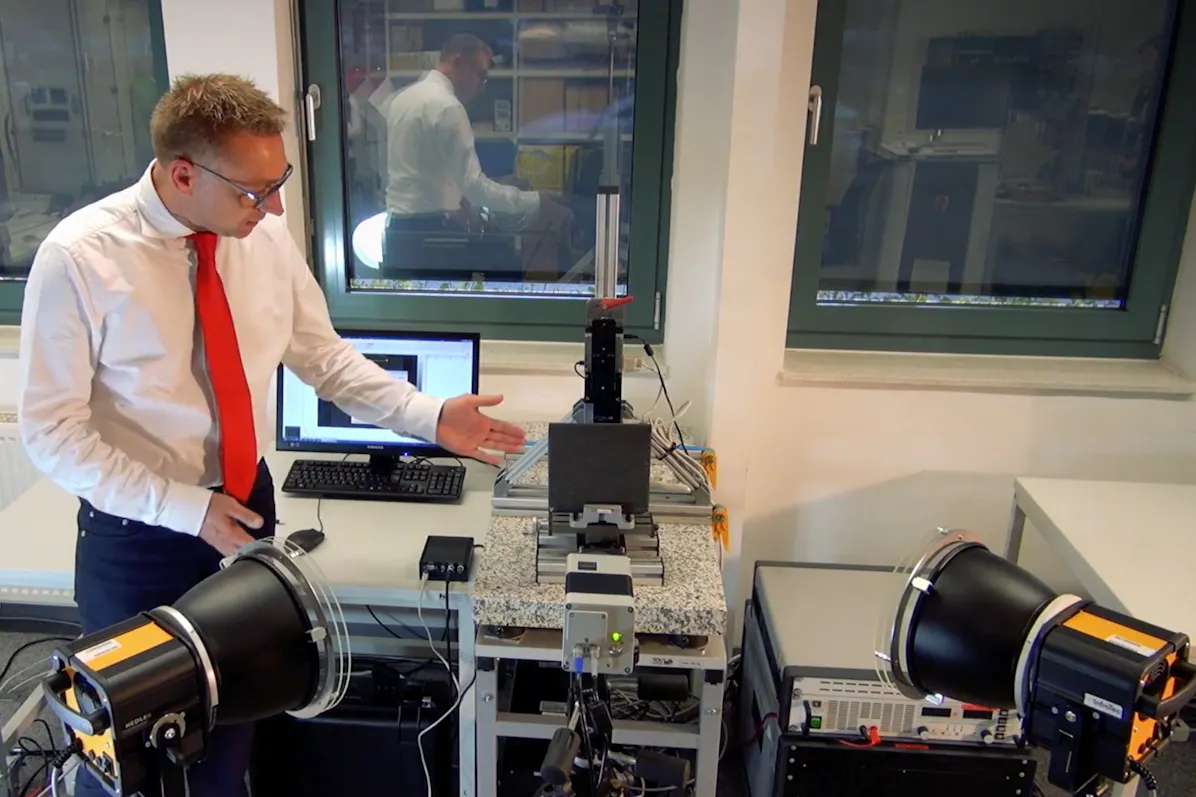

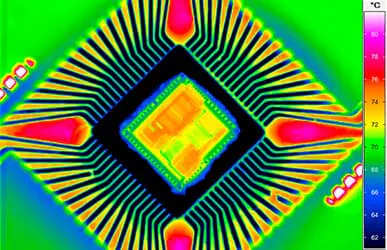

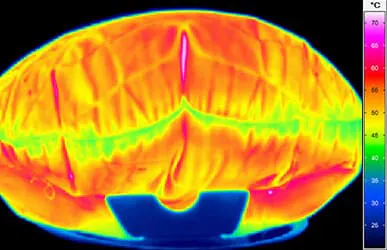

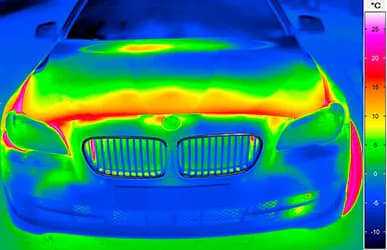

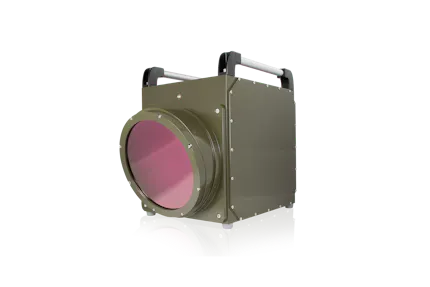

An infrared camera – also called IR camera, thermal imaging camera or thermal camera – is a measuring instrument used for non-contact measurements of the surface temperature of objects. Measuring temperature in this way enables you to visualise infrared radiation of objects or humans which are normally out of the normal visible spectrum. The infrared camera uses its integrated infrared detector to record the intensity and distribution of a certain spectrum of this electromagnetic radiation. The thermal camera is set up close to process it is controlling in order to immediately detect and rectify deviations from the parameters defined for this process. InfraTec provides such solutions for process monitoring and quality control as well as for research and development.

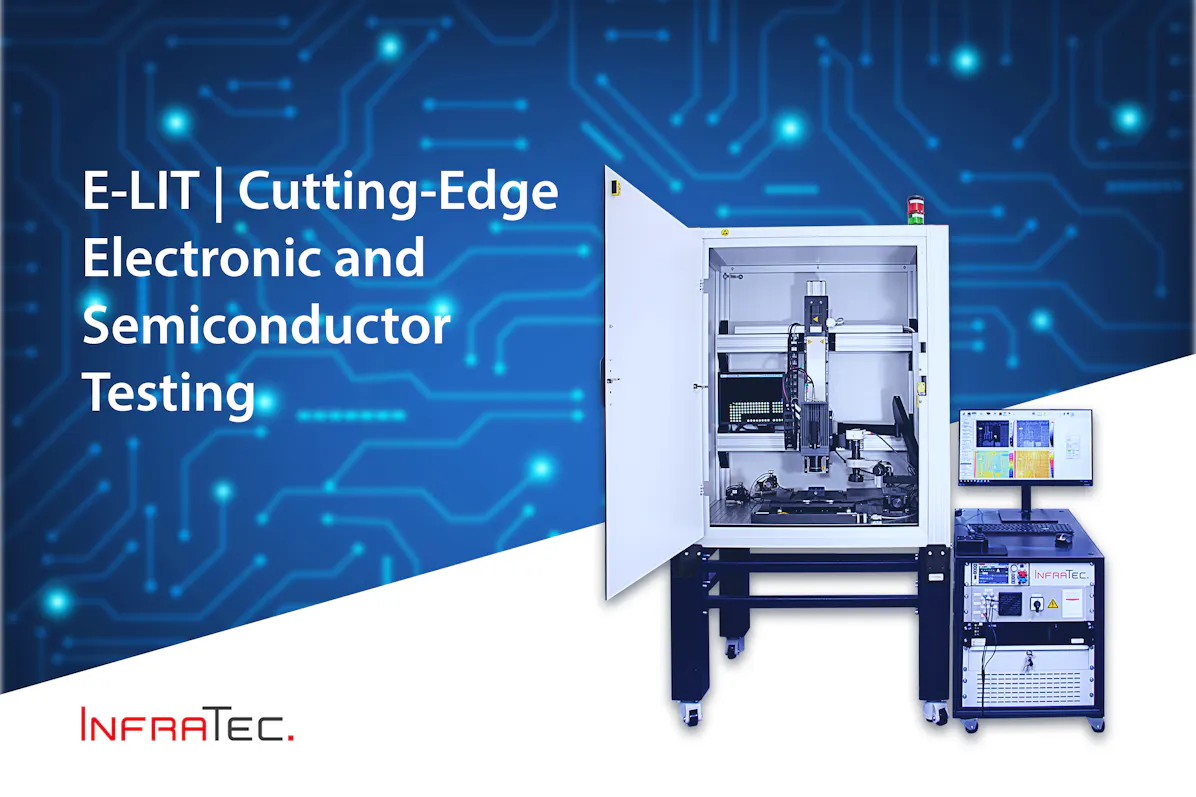

The benefit of non-contact temperature measurement technology is the capability to inspect objects non-destructively and contact-free and to make material conditions in deeper layers visible. The contact-free measurement of temperature distributions on objects or in processes constantly informs about the state of the object. Thus, deviations of the production standard can be recognised. In addition to the mobile infrared camera models, InfraTec has also developed various thermography automation solutions for process and quality control applications. InfraTec specialised on developing reliable high-class infrared camera models for all application fields of thermal imaging.

Not as a rule, since glass is transmittant by visible light in the same way as is near infrared, however, it is not beyond a wavelength of approx. 4 µm. This spectral range requires special infrared-transmittant window materials.

Especially during the production of thermally sensitive components, thermography is capable of giving vital information for quality assurance purposes. Even smallest temperature deviations can lead to serious quality loss, i.e. in the plastics or automotive industry. By setting up a thermal camera monitoring system, such faults can be recognised, documented and corrected immediately.

InfraTec offers a suitable infrared camera and ideal thermography software for every application field, stationary or mobile. The modular structure of the measurement devices makes it easy to meet every customer-specific demand.

Infrared Thermal Imaging in Stationary Use

An infrared camera is installed in close vicinity to the process, which has to be monitored. The infrared camera transmits all captured data to an evaluation unit. The evaluation unit compares the actual value to the defined target value by comparing the minimum, maximum and average values. A switch contact can be triggered by the transgression of thresholds, which will then set off an alarm. Appropriate countermeasures can then be taken.

InfraTec’s measurement devices are rugged, have been tested extensively and are conceived for continuous industrial use. Modern interface concepts allow for reliable camera control, data acquisition and online data evaluation, even over long distances. This makes thermal imaging ideal for automation solutions like slag detection, early fire detection or for inspections of solar cells and photovoltaic modules.

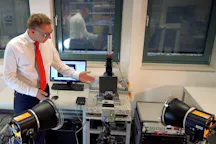

InfraTec is a Leading Thermal Imaging Expert

InfraTec has been offering a wide range of innovative high-class thermal imaging measurement devices since 1991. The quality of the high-performance infrared cameras is based on profound and permanent development processes. The range of services of the thermography division ranges from production and sale of infrared cameras to the supply with turn-key thermography automation solutions.

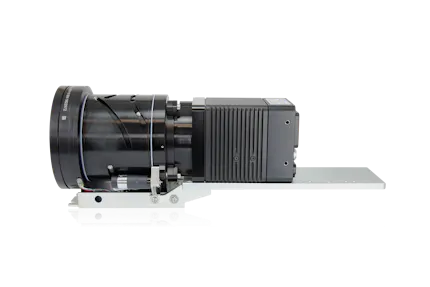

Choose Your Infrared Camera

Choose from more than 30 infrared camera models. Our product range includes includes compact and system cameras, high-end systems as well as zoom cameras and OEM solutions.